Ford Explorer: Glass, Frames and Mechanisms / Diagnosis and Testing - Glass, Frames and Mechanisms

Diagnostic Trouble Code (DTC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

Diagnostic Trouble Code Chart

| Module | DTC | Description | Action |

|---|---|---|---|

| DDM | B1088:83 | LIN Bus "B": Value of Signal Protection Calculation Incorrect | GO to Pinpoint Test A |

| DDM | B1088:87 | LIN Bus "B": Missing Message | GO to Pinpoint Test A |

| DDM | B1189:77 | Front Window Position Sensor: Commanded Position Not Reachable | GO to Pinpoint Test A |

| DDM | B118E:01 | Left Front Window: General Electrical Failure | GO to Pinpoint Test A |

| DDM | B12DC:01 | Front Window Motion/Position Sensor: General Electrical Failure | GO to Pinpoint Test A |

| DDM | B12DC:92 | Front Window Motion/Position Sensor: Performance or Incorrect Operation | GO to Pinpoint Test A |

| DDM | B13F1:01 | Driver Power Window Motor: General Electrical Failure | GO to Pinpoint Test A |

| DDM | B13F1:64 | Driver Power Window Motor: Signal Plausibility Failure | GO to Pinpoint Test A |

| DDM | U2013:24 | Switch Pack: Signal Stuck High | GO to Pinpoint Test A |

| PDM | B1189:77 | Front Window Position Sensor: Commanded Position Not Reachable | GO to Pinpoint Test B |

| PDM | B118F:01 | Right Front Window: General Electrical Failure | GO to Pinpoint Test B |

| PDM | B12DC:01 | Front Window Motion/Position Sensor: General Electrical Failure | GO to Pinpoint Test B |

| PDM | B12DC:92 | Front Window Motion/Position Sensor: Performance or Incorrect Operation | GO to Pinpoint Test B |

| PDM | B13E5:23 | Passenger Power Window Switch Up: Signal Stuck Low | GO to Pinpoint Test B |

| PDM | B13E6:23 | Passenger Power Window Switch Down: Signal Stuck Low | GO to Pinpoint Test B |

| PDM | B13F2:01 | Passenger Power Window Motor: General Electrical Failure | GO to Pinpoint Test B |

| PDM | B13F2:64 | Passenger Power Window Motor: Signal Plausibility Failure | GO to Pinpoint Test B |

Symptom Chart(s)

Symptom Chart: Glass, Frames and Mechanisms

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

Symptom Chart

| Condition | Possible Sources | Actions |

|---|---|---|

| All power windows are inoperative from the driver window control switch |

|

GO to Pinpoint Test H |

| Both rear passenger power windows are inoperative |

|

GO to Pinpoint Test I |

| A single power window is inoperative/does not operate correctly - LH front |

|

GO to Pinpoint Test A |

| A single power window is inoperative/does not operate correctly - RH front |

|

GO to Pinpoint Test B |

| A single power window is inoperative/does not operate correctly - LH rear |

|

GO to Pinpoint Test C |

| A single power window is inoperative/does not operate correctly - RH rear |

|

GO to Pinpoint Test D |

| The one-touch up feature is inoperative - front |

|

GO to Pinpoint Test E |

| The global open function is inoperative |

|

GO to Pinpoint Test J |

| The defrost system is inoperative |

|

GO to Pinpoint Test F |

| One or more individual defrost grid wires are inoperative |

|

REFER to: Heated Window Grid Wire Repair (501-11 Glass, Frames and Mechanisms, General Procedures). |

| The defrost system does not shut off automatically |

|

GO to Pinpoint Test G |

Pinpoint Test(s)

.jpg) PINPOINT TEST A : A SINGLE POWER WINDOW IS INOPERATIVE/DOES NOT OPERATE CORRECTLY- LH (LEFT-HAND)

FRONT

PINPOINT TEST A : A SINGLE POWER WINDOW IS INOPERATIVE/DOES NOT OPERATE CORRECTLY- LH (LEFT-HAND)

FRONT|

Refer to Wiring Diagrams Cell 100 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Glass, Frames and Mechanisms - System Operation and Component Description (501-11 Glass, Frames and Mechanisms, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

||||||||||||||||||||||||||||||

| A1 CHECK FOR DDM (DRIVER DOOR MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | ||||||||||||||||||||||||||||||

Are any DDM Diagnostic Trouble Codes (DTCs) present?

|

||||||||||||||||||||||||||||||

| A2 CHECK THE FRONT DOOR WINDOW CONTROL SWITCH PID (PARAMETER IDENTIFICATION) OPERATION | ||||||||||||||||||||||||||||||

Does the PID status agree with the driver window control switch as it is pressed and released?

|

||||||||||||||||||||||||||||||

| A3 CHECK FOR A SHORT TO VOLTAGE IN THE WINDOW UP/DOWN CIRCUITS | ||||||||||||||||||||||||||||||

Is any voltage present?

|

||||||||||||||||||||||||||||||

| A4 CHECK FOR A SHORT TO GROUND IN THE WINDOW UP/DOWN CIRCUITS | ||||||||||||||||||||||||||||||

Are the resistances greater than 10,000 ohms?

|

||||||||||||||||||||||||||||||

| A5 CHECK FOR AN OPEN IN THE WINDOW UP/DOWN CIRCUITS | ||||||||||||||||||||||||||||||

Are the resistances less than 3 ohms?

|

||||||||||||||||||||||||||||||

| A6 CHECK THE DDM (DRIVER DOOR MODULE) OUTPUT | ||||||||||||||||||||||||||||||

|

NOTICE: The following step uses a test lamp to simulate normal circuit loads. Use only a Rotunda Test Lamp (SGT27000) or 250- 300mA incandescent bulb test lamp. To avoid connector terminal damage, use the Rotunda Flex Probe kit for the test lamp probe connection to the vehicle. Do not use the test lamp probe directly on any connector.

Does the test light momentarily illuminate when the driver window control switch is activated in both up and down positions?

|

||||||||||||||||||||||||||||||

| A7 CHECK FOR VOLTAGE TO THE DRIVER WINDOW CONTROL SWITCH | ||||||||||||||||||||||||||||||

Is the voltage greater than 11 volts?

|

||||||||||||||||||||||||||||||

| A8 CHECK THE DRIVER WINDOW CONTROL SWITCH GROUND CIRCUIT | ||||||||||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

||||||||||||||||||||||||||||||

| A9 CHECK THE DRIVER WINDOW CONTROL SWITCH LIN (LOCAL INTERCONNECT NETWORK) CIRCUIT FOR AN OPEN | ||||||||||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

||||||||||||||||||||||||||||||

| A10 CHECK FOR CORRECT DDM (DRIVER DOOR MODULE) OPERATION | ||||||||||||||||||||||||||||||

Is the concern still present?

|

.jpg) PINPOINT TEST B : A SINGLE POWER WINDOW IS INOPERATIVE/DOES NOT OPERATE CORRECTLY - RH (RIGHT-HAND)

FRONT

PINPOINT TEST B : A SINGLE POWER WINDOW IS INOPERATIVE/DOES NOT OPERATE CORRECTLY - RH (RIGHT-HAND)

FRONT|

Refer to Wiring Diagrams Cell 100 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Glass, Frames and Mechanisms - System Operation and Component Description (501-11 Glass, Frames and Mechanisms, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

|||||||||||||||||||||||||||

| B1 CHECK FOR PDM (PASSENGER DOOR MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||||||||||||||||||||

Are any PDM Diagnostic Trouble Codes (DTCs) present?

|

|||||||||||||||||||||||||||

| B2 CHECK THE WINDOW OPERATION FROM THE DRIVER WINDOW CONTROL SWITCH | |||||||||||||||||||||||||||

Does the RH front power window operate correctly from the driver window control switch?

|

|||||||||||||||||||||||||||

| B3 CHECK THE WINDOW CONTROL SWITCH | |||||||||||||||||||||||||||

Did the RH front window control switch pass the component test?

|

|||||||||||||||||||||||||||

| B4 CHECK THE WINDOW CONTROL SWITCH UP/DOWN CIRCUITS | |||||||||||||||||||||||||||

Does the window operate upward and downward when the fused jumper wire is in place?

|

|||||||||||||||||||||||||||

| B5 CHECK THE WINDOW CONTROL SWITCH RETURN CIRCUIT FOR AN OPEN | |||||||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

|||||||||||||||||||||||||||

| B6 CHECK THE WINDOW CONTROL SWITCH CIRCUITS FOR A SHORT TO GROUND | |||||||||||||||||||||||||||

Are the resistances greater than 10,000 ohms?

|

|||||||||||||||||||||||||||

| B7 CHECK THE WINDOW CONTROL SWITCH CIRCUITS FOR A SHORT TO GROUND WITH THE WINDOW CONTROL SWITCH DISCONNECTED | |||||||||||||||||||||||||||

Are the resistances greater than 10,000 ohms?

|

|||||||||||||||||||||||||||

| B8 CHECK THE WINDOW CONTROL SWITCH CIRCUITS FOR AN OPEN | |||||||||||||||||||||||||||

Are the resistances less than 3 ohms?

|

|||||||||||||||||||||||||||

| B9 CHECK FOR A SHORT TO VOLTAGE IN THE WINDOW UP/DOWN CIRCUITS | |||||||||||||||||||||||||||

Is any voltage present?

|

|||||||||||||||||||||||||||

| B10 CHECK FOR A SHORT TO GROUND IN THE WINDOW UP/DOWN CIRCUITS | |||||||||||||||||||||||||||

Are the resistances greater than 10,000 ohms?

|

|||||||||||||||||||||||||||

| B11 CHECK FOR AN OPEN IN THE WINDOW UP/DOWN CIRCUITS | |||||||||||||||||||||||||||

Are the resistances less than 3 ohms?

|

|||||||||||||||||||||||||||

| B12 CHECK THE PDM (PASSENGER DOOR MODULE) OUTPUT | |||||||||||||||||||||||||||

|

NOTICE: The following step uses a test lamp to simulate normal circuit loads. Use only a Rotunda Test Lamp (SGT27000) or 250- 300mA incandescent bulb test lamp. To avoid connector terminal damage, use the Rotunda Flex Probe kit for the test lamp probe connection to the vehicle. Do not use the test lamp probe directly on any connector.

Does the test light momentarily illuminate when the window control switch is activated in both up and down positions?

|

|||||||||||||||||||||||||||

| B13 CHECK FOR CORRECT PDM (PASSENGER DOOR MODULE) OPERATION | |||||||||||||||||||||||||||

Is the concern still present?

|

.jpg) PINPOINT TEST C : A SINGLE POWER WINDOW IS INOPERATIVE/DOES NOT OPERATE CORRECTLY - LH (LEFT-HAND)

REAR

PINPOINT TEST C : A SINGLE POWER WINDOW IS INOPERATIVE/DOES NOT OPERATE CORRECTLY - LH (LEFT-HAND)

REAR|

Refer to Wiring Diagrams Cell 100 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Glass, Frames and Mechanisms - System Operation and Component Description (501-11 Glass, Frames and Mechanisms, Description and Operation). Possible Sources

Visual Inspection and Pre-checks

|

||||||||||||||||||||||

| C1 CHECK THE WINDOW OPERATION FROM THE DRIVER WINDOW CONTROL SWITCH | ||||||||||||||||||||||

Does the LH rear window operate from the driver window control switch?

|

||||||||||||||||||||||

| C2 CHECK FOR VOLTAGE FROM THE DRIVER WINDOW CONTROL SWITCH LOCK-OUT CIRCUIT | ||||||||||||||||||||||

Is the voltage greater than 11 volts?

|

||||||||||||||||||||||

| C3 CHECK THE LH (LEFT-HAND) REAR WINDOW CONTROL SWITCH POWER CIRCUIT FOR AN OPEN | ||||||||||||||||||||||

Is the voltage greater than 11 volts?

|

||||||||||||||||||||||

| C4 CHECK THE LH (LEFT-HAND) REAR WINDOW CONTROL SWITCH GROUND CIRCUIT FOR AN OPEN | ||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

||||||||||||||||||||||

| C5 CHECK THE DRIVER WINDOW CONTROL SWITCH OPERATION | ||||||||||||||||||||||

Are the voltages greater than 11 volts when the driver window control switch is pressed, and 0 volt when the switch is released?

|

||||||||||||||||||||||

| C6 CHECK THE POWER WINDOW CONTROL CIRCUITS FOR AN OPEN | ||||||||||||||||||||||

Are the resistances less than 3 ohms?

|

||||||||||||||||||||||

| C7 CHECK THE POWER WINDOW UPWARD AND/OR DOWNWARD OPERATION | ||||||||||||||||||||||

Does the LH rear window move up and/or down?

|

||||||||||||||||||||||

| C8 CHECK THE POWER WINDOW CIRCUITS FOR AN OPEN | ||||||||||||||||||||||

Are the resistances less than 3 ohms?

|

.jpg) PINPOINT TEST D : A SINGLE POWER WINDOW IS INOPERATIVE/DOES NOT OPERATE CORRECTLY - RH (RIGHT-HAND)

REAR

PINPOINT TEST D : A SINGLE POWER WINDOW IS INOPERATIVE/DOES NOT OPERATE CORRECTLY - RH (RIGHT-HAND)

REAR|

Refer to Wiring Diagrams Cell 100 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Glass, Frames and Mechanisms - System Operation and Component Description (501-11 Glass, Frames and Mechanisms, Description and Operation). Possible Sources

Visual Inspection and Pre-checks

|

||||||||||||||||||||||

| D1 CHECK THE WINDOW OPERATION FROM THE DRIVER WINDOW CONTROL SWITCH | ||||||||||||||||||||||

Does the RH rear window operate from the driver window control switch?

|

||||||||||||||||||||||

| D2 CHECK FOR VOLTAGE FROM THE DRIVER WINDOW CONTROL SWITCH LOCK-OUT CIRCUIT | ||||||||||||||||||||||

Is the voltage greater than 11 volts?

|

||||||||||||||||||||||

| D3 CHECK THE RH (RIGHT-HAND) REAR WINDOW CONTROL SWITCH POWER CIRCUIT FOR AN OPEN | ||||||||||||||||||||||

Is the voltage greater than 11 volts?

|

||||||||||||||||||||||

| D4 CHECK THE RH (RIGHT-HAND) REAR WINDOW CONTROL SWITCH GROUND CIRCUIT FOR AN OPEN | ||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

||||||||||||||||||||||

| D5 CHECK THE DRIVER WINDOW CONTROL SWITCH OPERATION | ||||||||||||||||||||||

Are the voltages greater than 11 volts when the driver window control switch is pressed, and 0 volt when the switch is released?

|

||||||||||||||||||||||

| D6 CHECK THE POWER WINDOW CONTROL CIRCUITS FOR AN OPEN | ||||||||||||||||||||||

Are the resistances less than 3 ohms?

|

||||||||||||||||||||||

| D7 CHECK THE POWER WINDOW UPWARD AND/OR DOWNWARD OPERATION | ||||||||||||||||||||||

Does the RH rear window move up and/or down?

|

||||||||||||||||||||||

| D8 CHECK THE POWER WINDOW CIRCUITS FOR AN OPEN | ||||||||||||||||||||||

Are the resistances less than 3 ohms?

|

.jpg) PINPOINT TEST E : THE ONE-TOUCH UP FEATURE IS INOPERATIVE - FRONT

PINPOINT TEST E : THE ONE-TOUCH UP FEATURE IS INOPERATIVE - FRONT|

Refer to Wiring Diagrams Cell 100 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Glass, Frames and Mechanisms - System Operation and Component Description (501-11 Glass, Frames and Mechanisms, Description and Operation). Possible Sources

|

||||

| E1 INITIALIZE THE SUSPECT POWER WINDOW | ||||

Is the one-touch up/down feature operating correctly?

|

.jpg) PINPOINT TEST F : THE DEFROST SYSTEM IS INOPERATIVE

PINPOINT TEST F : THE DEFROST SYSTEM IS INOPERATIVE|

Refer to Wiring Diagrams Cell 56 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Glass, Frames and Mechanisms - System Operation and Component Description (501-11 Glass, Frames and Mechanisms, Description and Operation). Possible Sources

Visual Inspection and Pre-checks

|

||||||||||

| F1 CHECK THE REAR WINDOW DEFROST GRID TERMINALS FOR DAMAGE | ||||||||||

Are the rear window defrost grid terminals OK?

|

||||||||||

| F2 CHECK THE REAR WINDOW DEFROST GRID VOLTAGE | ||||||||||

Is the voltage greater than 11 volts?

|

||||||||||

| F3 CHECK THE REAR WINDOW DEFROST GRID GROUND | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| F4 CHECK THE REAR WINDOW DEFROST FUSE | ||||||||||

Is the fuse OK?

|

||||||||||

| F5 CHECK THE REAR WINDOW DEFROST SWITCH PID (PARAMETER IDENTIFICATION) | ||||||||||

Does the PID agree with the rear window defrost switch status?

|

||||||||||

| F6 CHECK FOR BCMC (BODY CONTROL MODULE C) DIAGNOSTIC TROUBLE CODES (DTCS) | ||||||||||

Are any BCMC Diagnostic Trouble Codes (DTCs) present?

|

||||||||||

| F7 CHECK FOR CORRECT HVAC (HEATING, VENTILATION AND AIR CONDITIONING) MODULE OPERATION | ||||||||||

Is the concern still present?

|

||||||||||

| F8 CHECK FOR CORRECT BJB (BATTERY JUNCTION BOX) OPERATION | ||||||||||

Is the concern still present?

|

||||||||||

| F9 CHECK FOR CORRECT BJB (BATTERY JUNCTION BOX) AND BCMC (BODY CONTROL MODULE C) OPERATION | ||||||||||

Is the concern still present?

|

.jpg) PINPOINT TEST G : THE DEFROST SYSTEM DOES NOT SHUT OFF AUTOMATICALLY

PINPOINT TEST G : THE DEFROST SYSTEM DOES NOT SHUT OFF AUTOMATICALLY|

Refer to Wiring Diagrams Cell 56 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Glass, Frames and Mechanisms - System Operation and Component Description (501-11 Glass, Frames and Mechanisms, Description and Operation). Possible Sources

|

||||||||||

| G1 CHECK THE REAR WINDOW DEFROST OUTPUT CIRCUIT FOR A SHORT TO VOLTAGE | ||||||||||

Is any voltage present?

|

||||||||||

| G2 CHECK FOR CORRECT BJB (BATTERY JUNCTION BOX) OPERATION | ||||||||||

Is the concern still present?

|

.jpg) PINPOINT TEST H : ALL POWER WINDOWS ARE INOPERATIVE FROM THE DRIVER WINDOW CONTROL SWITCH

PINPOINT TEST H : ALL POWER WINDOWS ARE INOPERATIVE FROM THE DRIVER WINDOW CONTROL SWITCH |

Refer to Wiring Diagrams Cell 100 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Glass, Frames and Mechanisms - System Operation and Component Description (501-11 Glass, Frames and Mechanisms, Description and Operation). Possible Sources

|

||||

| H1 CHECK FOR DDM (DRIVER DOOR MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | ||||

Are any DDM Diagnostic Trouble Codes (DTCs) present?

|

||||

| H2 CHECK FOR CORRECT DRIVER WINDOW OPERATION | ||||

Is the concern still present?

|

.jpg) PINPOINT TEST I : BOTH REAR PASSENGER POWER WINDOWS ARE INOPERATIVE

PINPOINT TEST I : BOTH REAR PASSENGER POWER WINDOWS ARE INOPERATIVE |

Refer to Wiring Diagrams Cell 100 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Glass, Frames and Mechanisms - System Operation and Component Description (501-11 Glass, Frames and Mechanisms, Description and Operation). For police vehicles only, there is an in-line connector which, if disconnected, will disable LH and RH rear window operation except from the driver window control switch (regardless of the lock-out switch position). Possible Sources

|

||||||||||

| I1 CHECK THE REAR WINDOW MOTOR CIRCUIT FOR VOLTAGE | ||||||||||

Is the voltage greater than 11 volts?

|

||||||||||

| I2 CHECK FOR A SHORT TO GROUND IN THE POWER WINDOW SYSTEM | ||||||||||

Did the jumper wire fuse open during the test?

|

||||||||||

| I3 CHECK THE REAR WINDOW LOCK-OUT CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

.jpg) PINPOINT TEST J : THE GLOBAL OPEN FUNCTION IS INOPERATIVE

PINPOINT TEST J : THE GLOBAL OPEN FUNCTION IS INOPERATIVE|

Refer to Wiring Diagrams Cell 100 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Glass, Frames and Mechanisms - System Operation and Component Description (501-11 Glass, Frames and Mechanisms, Description and Operation). Possible Sources

Visual Inspection and Pre-checks

|

||||

| J1 VERIFY THE RKE (REMOTE KEYLESS ENTRY) LOCK/UNLOCK FUNCTION OPERATES CORRECTLY USING ALL OF THE RKE (REMOTE KEYLESS ENTRY) TRANSMITTERS | ||||

Did the RKE lock/unlock function operate correctly using the RKE transmitters?

|

Description and Operation - Glass, Frames and Mechanisms - System Operation and Component Description

Description and Operation - Glass, Frames and Mechanisms - System Operation and Component Description

System Operation

System Diagram - Power Windows

Front Power Windows

Item

Description

1

Driver Window Control Switch

2

Driver Door Window Regulator Motor

3

P..

General Procedures - Fixed Glass

General Procedures - Fixed Glass

Special Tool(s) /

General Equipment

Power Caulk Gun

Power Fixed Glass Removal Tool

Cold Knife

Knife

Vacuum Cleaner

Materials

Name

Specification

Sika® SikaTack® ..

Other information:

Ford Explorer 2020-2025 Service Manual: Diagnosis and Testing - Rear Drive Axle and Differential

Preliminary Inspection Visually inspect the housing, seals, drive pinion stem for obvious signs of mechanical damage. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to the next step If the cause is not visually evident, verify the symptom and REFER to Symptom Chart: NVH...

Ford Explorer 2020-2025 Service Manual: Removal and Installation - Selector Shaft Seal

Special Tool(s) / General Equipment 307-549Installer, Shift Shaft Fluid SealTKIT-2005D1-F1 Materials Name Specification Motorcraft® MERCON® ULV Automatic Transmission FluidXT-12-QULV WSS-M2C949-A, MERCON® ULV Removal With the vehicle in NEUTRAL, position it on a hoist...

Categories

- Manuals Home

- 6th Generation Explorer Owners Manual

- 6th Generation Explorer Service Manual

- Engine

- General Procedures - Brake Service Mode Activation and Deactivation

- Auxiliary Power Points

- New on site

- Most important about car

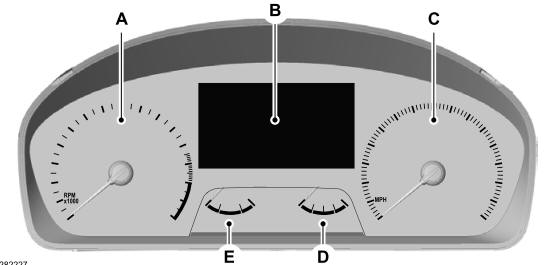

Gauges

4 Inch Display

A - Tachometer.

B - Information display.

C - Speedometer.

D - Fuel gauge.

E - Engine coolant temperature gauge.

.jpg) PINPOINT TEST A : A SINGLE POWER WINDOW IS INOPERATIVE/DOES NOT OPERATE CORRECTLY- LH (LEFT-HAND)

FRONT

PINPOINT TEST A : A SINGLE POWER WINDOW IS INOPERATIVE/DOES NOT OPERATE CORRECTLY- LH (LEFT-HAND)

FRONT.jpg)

.jpg)

.jpg)

.jpg)