Ford Explorer: Handles, Locks, Latches and Entry Systems / Diagnosis and Testing - Locks, Latches and Entry Systems

Diagnostic Trouble Code (DTC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

Diagnostic Trouble Code Chart

| Module | DTC | Description | Action |

|---|---|---|---|

| BCM | B108F:23 | Cabin Lock/Unlock Switch: Signal Stuck Low | GO to Pinpoint Test K |

| BCM | B10AB:00 | Remote Keyless Entry Synchronization: No Sub Type Information | GO to Pinpoint Test O |

| BCM | B10C7:01 | Interior Trunk Antenna: General Electrical Failure | GO to Pinpoint Test T |

| BCM | B1218:00 | Transmitter Identification Code: No Sub Type Information | GO to Pinpoint Test O |

| BCM | B126A:01 | Drivers Door Interior Lock Switch: General Electrical Failure | GO to Pinpoint Test K |

| BCM | B12EE:11 | Liftgate/Tailgate/Trunk Release: Circuit Short To Ground | GO to Pinpoint Test M |

| BCM | B12EE:12 | Liftgate/Tailgate/Trunk Release: Circuit Short To Battery | GO to Pinpoint Test M |

| BCM | B12EE:13 | Liftgate/Tailgate/Trunk Release: Circuit Open | GO to Pinpoint Test M |

| BCM | B12EE:15 | Liftgate/Tailgate/Trunk Release: Circuit Short To Battery or Open | GO to Pinpoint Test M |

| BCM | B1336:01 | Left Front Door External Antenna: General Electrical Failure | GO to Pinpoint Test S |

| BCM | B1337:01 | Right Front Door External Antenna: General Electrical Failure | GO to Pinpoint Test S |

| BCM | B1381:11 | Left Front Door Handle Proximity Sensor: Circuit Short to Ground | GO to Pinpoint Test S |

| BCM | B1381:15 | Left Front Door Handle Proximity Sensor: Circuit Short to Battery or Open | GO to Pinpoint Test S |

| BCM | B1381:29 | Left Front Door Handle Proximity Sensor: Signal Invalid | GO to Pinpoint Test S |

| BCM | B1382:11 | Right Front Door Handle Proximity Sensor: Circuit Short to Ground | GO to Pinpoint Test S |

| BCM | B1382:15 | Right Front Door Handle Proximity Sensor: Circuit Short to Battery or Open | GO to Pinpoint Test S |

| BCM | B1382:29 | Right Front Door Handle Proximity Sensor: Signal Invalid | GO to Pinpoint Test S |

| BCM | B14E9:01 | Liftgate Unlock Switch: General Electrical Failure | GO to Pinpoint Test M |

| BCM | B1560:49 | Driver Side Keypad: Internal Electronic Failure | GO to Pinpoint Test N |

| BCM | B1585:11 | Central Lock Output: Circuit Short To Ground | GO to Pinpoint Test J |

| BCM | B1585:12 | Central Lock Output: Circuit Short To Battery | GO to Pinpoint Test J |

| BCM | B1585:13 | Central Lock Output: Circuit Open | GO to Pinpoint Test J |

| BCM | B1586:11 | Central Unlock Output: Circuit Short To Ground | GO to Pinpoint Test J |

| BCM | B1586:12 | Central Unlock Output: Circuit Short To Battery | GO to Pinpoint Test J |

| BCM | B1586:13 | Central Unlock Output: Circuit Open | GO to Pinpoint Test J |

| BCM | B1587:11 | Driver Door Unlock Output: Short to Ground | GO to Pinpoint Test J |

| BCM | B1587:12 | Driver Door Unlock Output: Short to battery | GO to Pinpoint Test J |

| BCM | B1587:13 | Driver Door Unlock Output: Circuit Open | GO to Pinpoint Test J |

| BCM | B15D5:12 | Passenger Door Unlock Output: Short to Battery | GO to Pinpoint Test J |

| BCM | U0258:87 | Lost Communication With Radio Transceiver: Missing Message | GO to Pinpoint Test U |

| DDM | U0140:00 | Lost Communication With Body Control Module: No Sub-Type Information | GO to Pinpoint Test V |

| DDM | U0164:00 | Lost Communication With HVAC Control Module: No Sub-Type Information | GO to Pinpoint Test AA |

| DDM | U0208:00 | Lost Communication With "Seat Control Module A": No Sub-Type Information | GO to Pinpoint Test W |

| DDM | U0232:00 | Lost Communication With Side Obstacle Detection Control Module A: No Sub-Type Information | GO to Pinpoint Test X |

| DDM | U0233:00 | Lost Communication With Side Obstacle Detection Control Module - B: No Sub-Type Information | GO to Pinpoint Test Y |

| DDM | U0294:00 | Lost Communication With Powertrain Control Monitor Module: No Sub-Type Information | GO to Pinpoint Test AB |

| DDM | U2100:00 | Initial Configuration Not Complete: No Sub Type Information | GO to Pinpoint Test AC |

| DDM | U2200:00 | Control Module Configuration Memory Corrupt: No Sub Type Information | GO to Pinpoint Test AH |

| DDM | U3000:49 | Control Module: Internal Electronic Failure | GO to Pinpoint Test AH |

| DDM | U3003:16 | Battery Voltage: Circuit Voltage Below Threshold | GO to Pinpoint Test AF |

| DDM | U3003:17 | Battery Voltage: Circuit Voltage Above Threshold | GO to Pinpoint Test AG |

| PCM | P04B5:00 | Fuel Fill Door Stuck Open: No Sub-Type Information | GO to Pinpoint Test AK |

| PCM | P04BA:00 | Fuel Fill Door Position Sensor/Switch Circuit High: No Sub-Type Information | GO to Pinpoint Test AK |

| PCM | P04C1:00 | Fuel Fill Door Unlock Control Circuit Low: No Sub-Type Information | GO to Pinpoint Test AJ |

| PCM | P04C2:00 | Fuel Fill Door Unlock Control Circuit High: No Sub-Type Information | GO to Pinpoint Test AI |

| PCM | P04C9:00 | Fuel Fill Door Open Request Sensor/Switch Performance/Stuck Off: No Sub-Type Information | GO to Pinpoint Test AI |

| PCM | P04CA:00 | Fuel Fill Door Open Request Sensor/Switch Stuck Low: No Sub-Type Information | GO to Pinpoint Test AI |

| PCM | P04CB:00 | Fuel Fill Door Open Request Sensor/Switch Stuck High: No Sub-Type Information | GO to Pinpoint Test AI |

| PCM | P04CD:00 | Fuel Fill Door Open Request Sensor/Switch Stuck On: No Sub-Type Information | GO to Pinpoint Test AI |

| PCM | P1594:00 | Forced Engine Shutdown: Remote Start Fault, No Unattended Vehicle Timeout | GO to Pinpoint Test Z |

| PCM | P1595:00 | Forced Engine Shutdown: Remote Start System Fault, Transmissiom Range Not In Park Position | GO to Pinpoint Test Z |

| PDM | U0140:00 | Lost Communication With Body Control Module: No Sub-Type Information | GO to Pinpoint Test V |

| PDM | U0164:00 | Lost Communication With HVAC Control Module: No Sub-Type Information | GO to Pinpoint Test AA |

| PDM | U0208:00 | Lost Communication With "Seat Control Module A": No Sub-Type Information | GO to Pinpoint Test W |

| PDM | U0232:00 | Lost Communication With Side Obstacle Detection Control Module A: No Sub-Type Information | GO to Pinpoint Test X |

| PDM | U0233:00 | Lost Communication With Side Obstacle Detection Control Module B: No Sub-Type Information | GO to Pinpoint Test Y |

| PDM | U0294:00 | Lost Communication With Powertrain Control Monitor Module: No Sub-Type Information | GO to Pinpoint Test AB |

| PDM | U2100:00 | Initial Configuration Not Complete: No Sub Type Information | GO to Pinpoint Test AC |

| PDM | U2200:00 | Control Module Configuration Memory Corrupt: No Sub Type Information | GO to Pinpoint Test AH |

| PDM | U3000:49 | Control Module: Internal Electronic Failure | GO to Pinpoint Test AH |

| PDM | U3003:16 | Battery Voltage: Circuit Voltage Below Threshold | GO to Pinpoint Test AF |

| PDM | U3003:17 | Battery Voltage: Circuit Voltage Above Threshold | GO to Pinpoint Test AG |

| RTM | U1A00:00 | Private Communication Network: No Sub Type Information | GO to Pinpoint Test U |

Symptom Charts

Symptom Chart: Handles, Locks, Latches and Entry Systems - Mechanical

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

| Condition | Possible Sources | Actions |

|---|---|---|

| Hard to open or close a door from either door handle |

|

|

| A door is difficult or does not open from the exterior door handle |

|

|

| A door is difficult or does not open from the interior door handle |

|

|

| The exterior door release handle sticks |

|

|

| The interior door release handle sticks |

|

|

| Squeak-rattle-chucking noise from door |

|

|

| The manual door lock cylinder is inoperative |

|

|

| The ignition lock cylinder cannot be returned to the OFF position |

|

|

| The ignition lock cylinder is difficult to turn |

|

|

| The key is hard to insert into the ignition lock cylinder |

|

|

Symptom Chart: Handles, Locks, Latches and Entry Systems - Electrical

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

| Condition | Possible Sources | Actions |

|---|---|---|

| All door locks are inoperative |

|

|

| A single or more than one door lock is inoperative |

|

|

| The door locks operate only one way |

|

|

| All door locks are inoperative from one door lock control switch |

|

|

| The power liftgate is inoperative or does not operate correctly |

|

|

| The manual liftgate latch release is inoperative |

|

|

| The manual liftgate does not latch |

|

|

| The doors do not lock or unlock using the keyless entry keypad |

|

|

| The RKE transmitter is inoperative |

|

|

| An individual button/feature is inoperative from the RKE transmitter |

|

|

| The RKE transmitter has poor range performance |

|

|

| The remote start feature is inoperative |

|

|

| The smart unlock is inoperative |

|

|

| The 2-stage door unlocking does not operate correctly |

|

|

| A door passive entry feature is inoperative |

|

|

| The liftgate passive entry feature is inoperative |

|

|

| The fuel filler door lock is inoperative (except hybrid vehicle) |

|

|

| The fuel filler door release is inoperative (hybrid vehicle) |

|

|

| The fuel filler door does not latch (hybrid vehicle) |

|

|

Pinpoint Tests

.jpg) PINPOINT TEST A : HARD TO OPEN OR CLOSE A DOOR FROM EITHER DOOR HANDLE

PINPOINT TEST A : HARD TO OPEN OR CLOSE A DOOR FROM EITHER DOOR HANDLE|

Normal Operation and Fault Conditions The door latch can be actuated from the interior or exterior door handle. When actuated, the door latch releases and allows the door to open. If the door latch or the door hinges have insufficient lubrication or if the striker or door are misaligned, it causes extra force to be used when opening or closing the door. Possible Sources

|

||||

| A1 CHECK THE LATCH OPERATION FROM BOTH DOOR HANDLES | ||||

|

NOTE: Make sure the child safety lock is in the unlock position for the rear doors.

Does the door open normally from one of the door handles?

|

||||

| A2 CHECK THE LATCH OPERATION | ||||

Does the latch release easily?

|

||||

| A3 CHECK THE LATCH OPERATION AFTER LUBRICATION | ||||

Does the latch release easily?

|

||||

| A4 CHECK THE STRIKER ADJUSTMENT | ||||

Is the striker adjusted correctly?

|

||||

| A5 CHECK THE DOOR ALIGNMENT | ||||

Is the door aligned correctly?

|

.jpg) PINPOINT TEST B : A DOOR IS DIFFICULT OR DOES NOT OPEN FROM THE EXTERIOR DOOR HANDLE

PINPOINT TEST B : A DOOR IS DIFFICULT OR DOES NOT OPEN FROM THE EXTERIOR DOOR HANDLE|

Normal Operation and Fault Conditions The exterior door handle is connected to the door latch with an actuating cable. When the exterior door handle is pulled, the actuating cable pulls on the latch lever. When the latch lever moves, the door latch releases, allowing the door to open. Possible Sources

|

||||

| B1 CHECK THE LATCH OPERATION FROM BOTH DOOR HANDLES | ||||

Does the door open normally from one of the door handles?

|

||||

| B2 CHECK THE EXTERIOR DOOR HANDLE AND CABLE OPERATION | ||||

Are any of the exterior door handle components or linkages binding or broken?

|

||||

| B3 CHECK THE EXTERIOR DOOR HANDLE REINFORCEMENT | ||||

Does the exterior door handle operate correctly?

|

.jpg) PINPOINT TEST C : A DOOR IS DIFFICULT OR DOES NOT OPEN FROM THE INTERIOR DOOR HANDLE

PINPOINT TEST C : A DOOR IS DIFFICULT OR DOES NOT OPEN FROM THE INTERIOR DOOR HANDLE|

Normal Operation and Fault Conditions The interior door handle is connected to the door latch by an actuating cable. When the interior door handle is pulled, the cable pulls on the latch lever. When the latch lever moves, the door latch releases, allowing the door to open. Possible Sources

Visual Inspection and Pre-checks

|

||||

| C1 CHECK THE LATCH OPERATION FROM BOTH DOOR HANDLES | ||||

|

NOTE: Make sure the child safety lock is in the unlock position for the rear doors.

Does the door open normally from one of the door handles?

|

||||

| C2 CHECK THE INTERIOR DOOR HANDLE AND CABLE/LINKAGE OPERATION | ||||

Are any of the interior door handle components or cable/linkages binding or broken?

|

.jpg) PINPOINT TEST D : THE EXTERIOR DOOR RELEASE HANDLE STICKS

PINPOINT TEST D : THE EXTERIOR DOOR RELEASE HANDLE STICKS|

Normal Operation and Fault Conditions The exterior door handle is connected to the door latch with an actuating cable. When the exterior door handle is pulled, the actuating cable pulls on the latch lever. When the latch lever moves, the door latch releases, allowing the door to open. The handle has a return spring to make sure the handle returns to a closed position. Possible Sources

|

||||

| D1 CHECK FOR A BROKEN RETURN SPRING | ||||

Does the exterior door handle return to a closed position once released?

|

||||

| D2 CHECK THE EXTERIOR DOOR HANDLE AND LINKAGE OPERATION | ||||

Are any of the exterior door handle components or linkages binding?

|

.jpg) PINPOINT TEST E : THE INTERIOR DOOR RELEASE HANDLE STICKS

PINPOINT TEST E : THE INTERIOR DOOR RELEASE HANDLE STICKS|

Normal Operation and Fault Conditions The interior door handle is connected to the door latch by an actuating cable. When the interior door handle is pulled, the cable pulls on the latch lever. When the latch lever is moved, the door latch releases, allowing the door to open. The handle has a return spring to make sure the handle returns to a closed position. Possible Sources

|

||||

| E1 CHECK FOR A BROKEN RETURN SPRING | ||||

Does the interior door handle return to a closed position once released?

|

||||

| E2 CHECK THE INTERIOR DOOR HANDLE CABLE OPERATION | ||||

Is the door latch release cable OK?

|

.jpg) PINPOINT TEST F : SQUEAK-RATTLE-CHUCKING NOISE FROM DOOR

PINPOINT TEST F : SQUEAK-RATTLE-CHUCKING NOISE FROM DOOR|

Possible Sources

|

||||

| F1 CHECK FOR ANY LOOSE COMPONENTS | ||||

Are there any loose components inside the door?

|

||||

| F2 CHECK THE STRIKER ADJUSTMENT | ||||

Is the striker adjusted correctly?

|

||||

| F3 CHECK THE DOOR ALIGNMENT | ||||

Is the door aligned correctly?

|

||||

| F4 CHECK THE LATCH OPERATION AFTER LUBRICATION | ||||

Is the original noise still present after the latch is lubricated?

|

.jpg) PINPOINT TEST G : THE MANUAL DOOR LOCK CYLINDER INOPERATIVE

PINPOINT TEST G : THE MANUAL DOOR LOCK CYLINDER INOPERATIVE|

Normal Operation and Fault Conditions The door lock cylinder is connected to the door latch via a lock rod and can be used to manually lock/unlock the door. Possible Sources

|

||||

| G1 CHECK THE LOCK AND UNLOCK OPERATION | ||||

Does the door lock cylinder freely rotate without locking and unlocking the door?

|

||||

| G2 CHECK THE DOOR LOCK CYLINDER (FREE-SPIN) | ||||

Does the key in the door lock cylinder rotate freely while the lever is stationary?

|

||||

| G3 CHECK THE DOOR LOCK CYLINDER LINKAGE CONNECTION | ||||

Is the door lock cylinder rod and lever disconnected?

|

||||

| G4 CHECK THE LOCK CYLINDER OPERATION AFTER LUBRICATION | ||||

Does the door lock and unlock using the door lock cylinder?

|

||||

| G5 CHECK THE DOOR LOCK CYLINDER FOR BINDING | ||||

Does the door lock cylinder rotate freely?

|

||||

| G6 CHECK THE DOOR LOCK CYLINDER LINKAGE | ||||

Is the door lock cylinder rod and lever binding, damaged or disconnected?

|

.jpg) PINPOINT TEST H : THE IGNITION LOCK CYLINDER IS DIFFICULT TO TURN

PINPOINT TEST H : THE IGNITION LOCK CYLINDER IS DIFFICULT TO TURN|

Normal Operation and Fault Conditions The ignition lock cylinder mechanically rotates the ignition switch within the ignition lock cylinder housing. Insertion and extraction of the key and rotation of the lock cylinder using a correctly cut key should be smooth and require minimal effort. Possible Sources

|

||||

| H1 CHECK THE KEY | ||||

Is the key correctly cut and free of burrs and damage?

|

||||

| H2 CHECK THE IGNITION LOCK CYLINDER OPERATION | ||||

Does the key rotate through all ignition switch positions without excessive effort?

|

||||

| H3 CHECK THE IGNITION LOCK CYLINDER WHILE INSERTING THE KEY | ||||

Does the key insert and remove freely into the ignition lock cylinder?

|

||||

| H4 CHECK THE IGNITION LOCK CYLINDER FOR BINDING ROTATION | ||||

Does the ignition lock cylinder rotate freely?

|

.jpg) PINPOINT TEST I : ALL DOOR LOCKS ARE INOPERATIVE

PINPOINT TEST I : ALL DOOR LOCKS ARE INOPERATIVE|

Refer to Wiring Diagrams Cell 117 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Handles, Locks, Latches and Entry Systems - Overview (501-14 Handles, Locks, Latches and Entry Systems, Description and Operation). Possible Sources

|

||||||||||

| NOTICE: Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may damage the connector. | ||||||||||

| I1 CHECK FOR BCM (BODY CONTROL MODULE) , DDM (DRIVER DOOR MODULE) AND PDM (PASSENGER DOOR MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | ||||||||||

Are any Diagnostic Trouble Codes (DTCs) present?

|

||||||||||

| I2 VERIFY THE OPERATION OF BOTH DOOR LOCK CONTROL SWITCHES | ||||||||||

Does any door lock operate?

|

||||||||||

| I3 CHECK IF THE LOCKS OPERATE IN ONLY ONE DIRECTION | ||||||||||

Are all the door locks inoperative from both switch positions (lock and unlock) of either door lock control switch?

|

||||||||||

| I4 CHECK THE ALL DOOR LOCK CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| I5 CHECK FOR CORRECT BCM (BODY CONTROL MODULE) OPERATION | ||||||||||

Is the concern still present?

|

.jpg) PINPOINT TEST J : A SINGLE OR MORE THAN ONE DOOR LOCK IS INOPERATIVE

PINPOINT TEST J : A SINGLE OR MORE THAN ONE DOOR LOCK IS INOPERATIVE|

Refer to Wiring Diagrams Cell 117 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Handles, Locks, Latches and Entry Systems - Overview (501-14 Handles, Locks, Latches and Entry Systems, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

|||||||||||||||||||||||||||||||||

| J1 CHECK THE DOOR LATCH FOR BINDING | |||||||||||||||||||||||||||||||||

Does the door lock and unlock?

|

|||||||||||||||||||||||||||||||||

| J2 CHECK THE BCM (BODY CONTROL MODULE) ALL LOCK OUTPUT CIRCUIT FOR AN OPEN | |||||||||||||||||||||||||||||||||

|

NOTICE: The following step uses a test lamp to simulate normal circuit loads. Use only a Rotunda Test Lamp (SGT27000) or 250-300mA incandescent bulb test lamp. To avoid connector terminal damage, use the Rotunda Flex Probe kit for the test lamp probe connection to the vehicle. Do not use the test lamp probe directly on any connector.

Does the test lamp momentarily illuminate?

|

|||||||||||||||||||||||||||||||||

| J3 CHECK THE BCM (BODY CONTROL MODULE) UNLOCK OUTPUT CIRCUIT FOR AN OPEN | |||||||||||||||||||||||||||||||||

|

NOTICE: The following step uses a test lamp to simulate normal circuit loads. Use only a Rotunda Test Lamp (SGT27000) or 250-300mA incandescent bulb test lamp. To avoid connector terminal damage, use the Rotunda Flex Probe kit for the test lamp probe connection to the vehicle. Do not use the test lamp probe directly on any connector.

Does the test lamp momentarily illuminate?

|

|||||||||||||||||||||||||||||||||

| J4 CHECK FOR CORRECT BCM (BODY CONTROL MODULE) OPERATION | |||||||||||||||||||||||||||||||||

Is the concern still present?

|

.jpg) PINPOINT TEST K : THE DOOR LOCKS OPERATE ONLY ONE WAY

PINPOINT TEST K : THE DOOR LOCKS OPERATE ONLY ONE WAY|

Refer to Wiring Diagrams Cell 117 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Handles, Locks, Latches and Entry Systems - Overview (501-14 Handles, Locks, Latches and Entry Systems, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

||||||||||||||||||||||

| K1 CHECK FOR DDM (DRIVER DOOR MODULE) / PDM (PASSENGER DOOR MODULE) DTC (DIAGNOSTIC TROUBLE CODE) B108F:23 | ||||||||||||||||||||||

Is DTC B108F:23 present?

|

||||||||||||||||||||||

| K2 ISOLATE THE DOOR LOCK CONTROL SWITCH | ||||||||||||||||||||||

Is DTC B108F:23 still present?

|

||||||||||||||||||||||

| K3 CHECK THE DOOR LOCK CONTROL SWITCH INPUT CIRCUITS FOR A SHORT TO GROUND | ||||||||||||||||||||||

Are the resistances greater than 10,000 ohms?

|

||||||||||||||||||||||

| K4 CHECK THE LOCK REQUEST INPUT CIRCUIT | ||||||||||||||||||||||

Do the doors lock?

|

||||||||||||||||||||||

| K5 CHECK THE LOCK REQUEST INPUT CIRCUIT FOR AN OPEN | ||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

||||||||||||||||||||||

| K6 CHECK THE UNLOCK REQUEST INPUT CIRCUIT | ||||||||||||||||||||||

Do the doors unlock?

|

||||||||||||||||||||||

| K7 CHECK THE UNLOCK REQUEST INPUT CIRCUIT FOR AN OPEN | ||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

||||||||||||||||||||||

| K8 CHECK FOR CORRECT PDM (PASSENGER DOOR MODULE) OPERATION | ||||||||||||||||||||||

Is the concern still present?

|

||||||||||||||||||||||

| K9 CHECK FOR CORRECT DDM (DRIVER DOOR MODULE) OPERATION | ||||||||||||||||||||||

Is the concern still present?

|

.jpg) PINPOINT TEST L : ALL DOOR LOCKS ARE INOPERATIVE FROM ONE DOOR LOCK CONTROL SWITCH

PINPOINT TEST L : ALL DOOR LOCKS ARE INOPERATIVE FROM ONE DOOR LOCK CONTROL SWITCH |

Refer to Wiring Diagrams Cell 117 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Handles, Locks, Latches and Entry Systems - Overview (501-14 Handles, Locks, Latches and Entry Systems, Description and Operation). Possible Sources

Visual Inspection and Pre-checks

|

||||||||||||||||||||||||||||||||||||||||

| L1 CHECK FOR COMMUNICATION TO THE DDM (DRIVER DOOR MODULE) AND PDM (PASSENGER DOOR MODULE) | ||||||||||||||||||||||||||||||||||||||||

Does the DDM and the PDM pass the network test?

|

||||||||||||||||||||||||||||||||||||||||

| L2 BYPASS THE DOOR LOCK CONTROL SWITCH | ||||||||||||||||||||||||||||||||||||||||

Do the doors lock and unlock?

|

||||||||||||||||||||||||||||||||||||||||

| L3 CHECK THE DOOR LOCK CONTROL SWITCH GROUND CIRCUIT FOR AN OPEN | ||||||||||||||||||||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

||||||||||||||||||||||||||||||||||||||||

| L4 CHECK FOR CORRECT PDM (PASSENGER DOOR MODULE) OPERATION | ||||||||||||||||||||||||||||||||||||||||

Is the concern still present?

|

||||||||||||||||||||||||||||||||||||||||

| L5 CHECK FOR CORRECT DDM (DRIVER DOOR MODULE) OPERATION | ||||||||||||||||||||||||||||||||||||||||

Is the concern still present?

|

.jpg) PINPOINT TEST M : THE MANUAL LIFTGATE LATCH RELEASE IS INOPERATIVE

PINPOINT TEST M : THE MANUAL LIFTGATE LATCH RELEASE IS INOPERATIVE|

Refer to Wiring Diagrams Cell 117 for schematic and connector information. Refer to Wiring Diagrams Cell 96 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Handles, Locks, Latches and Entry Systems - Overview (501-14 Handles, Locks, Latches and Entry Systems, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

Visual Inspection and Pre-checks

|

||||||||||||||||||

| M1 CHECK THE LIFTGATE LATCH MANUAL RELEASE | ||||||||||||||||||

Does the liftgate latch release?

|

||||||||||||||||||

| M2 CHECK THE LIFTGATE RELEASE INPUT FOR A SHORT TO GROUND USING THE BCM (BODY CONTROL MODULE) LIFTGATE RELEASE SWITCH STATUS (LFTGATE_R_SW) PID (PARAMETER IDENTIFICATION) | ||||||||||||||||||

Does the PID indicate the liftgate release switch is continuously pressed?

|

||||||||||||||||||

| M3 CHECK THE LIFTGATE RELEASE SWITCH USING THE BCM (BODY CONTROL MODULE) LIFTGATE RELEASE SWITCH STATUS (LFTGATE_R_SW) PID (PARAMETER IDENTIFICATION) | ||||||||||||||||||

Does the PID continue to indicate the switch is pressed?

|

||||||||||||||||||

| M4 CHECK THE LIFTGATE RELEASE SWITCH INPUT CIRCUIT FOR A SHORT TO GROUND | ||||||||||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||||||||||

| M5 CHECK THE BCM (BODY CONTROL MODULE) LIFTGATE RELEASE SWITCH STATUS (LFTGATE_R_SW) PID (PARAMETER IDENTIFICATION) | ||||||||||||||||||

Does the PID indicate the switch is pressed?

|

||||||||||||||||||

| M6 BYPASS THE LIFTGATE RELEASE SWITCH WHILE MONITORING THE BCM (BODY CONTROL MODULE) LIFTGATE RELEASE SWITCH STATUS (LFTGATE_R_SW) PID (PARAMETER IDENTIFICATION) | ||||||||||||||||||

Does the PID indicate the switch is pressed?

|

||||||||||||||||||

| M7 CHECK THE LIFTGATE RELEASE SWITCH INPUT CIRCUIT FOR AN OPEN | ||||||||||||||||||

Is the resistance less than 3 ohms?

|

||||||||||||||||||

| M8 CHECK FOR VOLTAGE TO THE LIFTGATE LATCH RELEASE MOTOR | ||||||||||||||||||

|

NOTICE: The following step uses a test lamp to simulate normal circuit loads. Use only a Rotunda Test Lamp (SGT27000) or 250-300mA incandescent bulb test lamp. To avoid connector terminal damage, use the Rotunda Flex Probe kit for the test lamp probe connection to the vehicle. Do not use the test lamp probe directly on any connector.

Does the test lamp momentarily illuminate?

|

||||||||||||||||||

| M9 CHECK THE LIFTGATE LATCH RELEASE MOTOR GROUND CIRCUIT FOR AN OPEN | ||||||||||||||||||

|

NOTICE: The following step uses a test lamp to simulate normal circuit loads. Use only a Rotunda Test Lamp (SGT27000) or 250-300mA incandescent bulb test lamp. To avoid connector terminal damage, use the Rotunda Flex Probe kit for the test lamp probe connection to the vehicle. Do not use the test lamp probe directly on any connector.

Does the test lamp momentarily illuminate?

|

||||||||||||||||||

| M10 CHECK THE LIFTGATE LATCH RELEASE MOTOR VOLTAGE SUPPLY CIRCUIT FOR A SHORT TO GROUND | ||||||||||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||||||||||

| M11 CHECK THE LIFTGATE LATCH RELEASE MOTOR VOLTAGE SUPPLY CIRCUIT FOR AN OPEN | ||||||||||||||||||

Is the resistance less than 3 ohms?

|

||||||||||||||||||

| M12 CHECK FOR CORRECT BCM (BODY CONTROL MODULE) OPERATION | ||||||||||||||||||

Is the concern still present?

|

.jpg) PINPOINT TEST N : THE DOORS DO NOT LOCK OR UNLOCK USING THE KEYLESS ENTRY KEYPAD

PINPOINT TEST N : THE DOORS DO NOT LOCK OR UNLOCK USING THE KEYLESS ENTRY KEYPAD|

Refer to Wiring Diagrams Cell 117 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Handles, Locks, Latches and Entry Systems - Overview (501-14 Handles, Locks, Latches and Entry Systems, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

Visual Inspection and Pre-checks

|

||||||||||

| N1 CHECK POWER LOCK OPERATION FROM THE DOOR LOCK CONTROL SWITCH | ||||||||||

Do the doors lock and unlock?

|

||||||||||

| N2 CHECK THE KEYLESS ENTRY KEYPAD VOLTAGE SUPPLY CIRCUIT FOR VOLTAGE | ||||||||||

Is the voltage greater than 11 volts?

|

||||||||||

| N3 CHECK THE KEYLESS ENTRY KEYPAD VOLTAGE SUPPLY CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| N4 CHECK THE KEYLESS ENTRY KEYPAD GROUND CIRCUIT FOR AN OPEN | ||||||||||

Is the voltage greater than 11 volts?

|

||||||||||

| N5 CHECK THE KEYLESS ENTRY KEYPAD LIN CIRCUIT FOR A SHORT TO VOLTAGE | ||||||||||

Is any voltage present?

|

||||||||||

| N6 CHECK THE KEYLESS ENTRY KEYPAD LIN CIRCUIT FOR A SHORT TO GROUND | ||||||||||

Are the resistance greater than 10,000 ohms?

|

||||||||||

| N7 CHECK THE KEYLESS ENTRY KEYPAD LIN CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| N8 CHECK FOR CORRECT BCM (BODY CONTROL MODULE) OPERATION | ||||||||||

Is the concern still present?

|

.jpg) PINPOINT TEST O : THE RKE (REMOTE KEYLESS ENTRY)

TRANSMITTER IS INOPERATIVE

PINPOINT TEST O : THE RKE (REMOTE KEYLESS ENTRY)

TRANSMITTER IS INOPERATIVE|

Normal Operation and Fault Conditions

REFER to: Handles, Locks, Latches and Entry Systems - Overview (501-14 Handles, Locks, Latches and Entry Systems, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

Visual Inspection and Pre-checks

|

|||||||||

| NOTE: All customer keys/key fobs need to be present when diagnosing the RKE system. | |||||||||

| NOTE: Using a diagnostic scan tool to compare the BCM TIC_xx_BCM (Programmed Transmitter ID Code (TIC) Value x) PID to the RTM RTM Lst_Xm_ID_Cd (Last Received Transmitter ID Code (TIC)) PID can be used to verify if a key in question is programmed to the vehicle.. | |||||||||

| O1 CHECK FOR THE CORRECT KEYS/KEY FOBS | |||||||||

Are the correct keys present?

|

|||||||||

| O2 CHECK IF THE KEYS START THE VEHICLE (VEHICLES NOT EQUIPPED WITH PUSH BUTTON START) | |||||||||

Do both keys start the vehicle?

|

|||||||||

| O3 CHECK THE BCM (BODY CONTROL MODULE) UNLIMITED KEY MODE | |||||||||

|

NOTE: When the BCM is set to Unlimited Key mode, the IKT keys still start the vehicle but the RKE functionality is inoperative. The BCM only recognizes the first 2 keys reprogrammed for RKE functionality after it is set to Unlimited Key mode.

Is the BCM Unlimited Key mode enabled?

|

|||||||||

| O4 CHECK IF THE KEYS START THE VEHICLE (VEHICLES EQUIPPED WITH PUSH BUTTON START) | |||||||||

Do both keys start the vehicle?

|

|||||||||

| O5 CHECK FOR REDUCED RANGE | |||||||||

|

NOTE: Make sure the vehicle is in an open area with no other large metal objects near, such as other vehicles or steel buildings. NOTE: If the RKE functions when near the vehicle, but not at approximately 30m (98 ft), a poor range concern is present.

Does any key experience a poor range concern?

|

|||||||||

| O6 CHECK THE RKE (REMOTE KEYLESS ENTRY) FUNCTIONALITY OF THE KEYS/KEY FOBS | |||||||||

Are all the RKE functions inoperative from both keys/key fobs?

|

|||||||||

| O7 CHECK THE RKE (REMOTE KEYLESS ENTRY) FUNCTIONALITY OF THE SUSPECT KEY/KEY FOB | |||||||||

Does any RKE function operate?

|

|||||||||

| O8 CHECK THE NO (TIC) OUT OF SYNC (TIC-NONE_OOS) PID (PARAMETER IDENTIFICATION) | |||||||||

Does the PID indicate On?

|

|||||||||

| O9 RESYNCHRONIZE THE INOPERATIVE KEY BY CYCLING THE IGNITION | |||||||||

Does the suspect key operate correctly now?

|

|||||||||

| O10 RESYNCHRONIZE THE INOPERATIVE KEY FOB | |||||||||

Does the suspect key fob operate correctly now?

|

|||||||||

| O11 RESYNCHRONIZE THE INOPERATIVE PASSIVE KEY | |||||||||

Does the suspect key operate correctly now?

|

|||||||||

| O12 RESYNCHRONIZE THE INOPERATIVE KEY USING THE SECOND KEY/KEY FOB | |||||||||

Does the suspect key/key fob operate correctly now?

|

|||||||||

| O13 CHECK THE (RKE) REMOTE BATTERY LOW (RKE_BATT_LOW) PID (PARAMETER IDENTIFICATION) | |||||||||

Does the PID indicate Off?

|

|||||||||

| O14 CHECK THE KEY/KEY FOB BATTERY | |||||||||

Is the voltage greater than 2.5 volts?

|

|||||||||

| O15 CHECK THE PASSIVE KEY BATTERIES | |||||||||

|

NOTE: Do not clean off any grease from the battery terminals on the back surface of the circuit board.

Are the voltages greater than 2.5 volts?

|

|||||||||

| O16 PROGRAM THE SUSPECT KEY/KEY FOB | |||||||||

Does the RKE functionality operate?

|

|||||||||

| O17 CHECK FOR COMMUNICATION WITH THE BCM (BODY CONTROL MODULE) AND THE RTM (RADIO TRANSCEIVER MODULE) | |||||||||

Does the BCM and the RTM pass the network test?

|

|||||||||

| O18 CHECK FOR RTM (RADIO TRANSCEIVER MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||

Are any Diagnostic Trouble Codes (DTCs) present?

|

|||||||||

| O19 CHECK FOR BCM (BODY CONTROL MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||

Are any Diagnostic Trouble Codes (DTCs) present?

|

.jpg) PINPOINT TEST P : AN INDIVIDUAL BUTTON/FEATURE IS INOPERATIVE FROM THE RKE (REMOTE KEYLESS ENTRY)

TRANSMITTER

PINPOINT TEST P : AN INDIVIDUAL BUTTON/FEATURE IS INOPERATIVE FROM THE RKE (REMOTE KEYLESS ENTRY)

TRANSMITTER|

Normal Operation and Fault Conditions

REFER to: Handles, Locks, Latches and Entry Systems - Overview (501-14 Handles, Locks, Latches and Entry Systems, Description and Operation). Possible Sources

Visual Inspection and Pre-checks

|

||||

| P1 VERIFY THE DOOR LOCK OPERATION | ||||

Do the door locks operate?

|

||||

| P2 VERIFY THE HORN OPERATION USING THE BCM (BODY CONTROL MODULE) PID (PARAMETER IDENTIFICATION) (HORN_RELAY) | ||||

Does the horn sound when commanded on?

|

||||

| P3 VERIFY THE HAZARD LAMP OPERATION | ||||

Do the hazard lamps operate correctly?

|

||||

| P4 VERIFY THE LIFTGATE LATCH RELEASE OPERATION | ||||

Does the liftgate latch release (manual liftgate) or the liftgate power open (power liftgate)?

|

||||

| P5 CHECK THE LOCK AND UNLOCK BUTTONS | ||||

Do the doors lock and unlock?

|

||||

| P6 CHECK THE LIFTGATE BUTTON | ||||

Does the liftgate latch release (manual liftgate) or the power open (power liftgate)?

|

||||

| P7 CHECK THE PANIC ALARM/VEHICLE LOCATOR BUTTON | ||||

Do the exterior lamps flash and the horn sound?

|

||||

| P8 VERIFY THE REMOTE START OPERATION | ||||

Does the vehicle remotely start?

|

.jpg) PINPOINT TEST Q : THE RKE (REMOTE KEYLESS ENTRY)

TRANSMITTER HAS POOR RANGE PERFORMANCE

PINPOINT TEST Q : THE RKE (REMOTE KEYLESS ENTRY)

TRANSMITTER HAS POOR RANGE PERFORMANCE|

Normal Operation and Fault Conditions

REFER to: Handles, Locks, Latches and Entry Systems - Overview (501-14 Handles, Locks, Latches and Entry Systems, Description and Operation). Possible Sources

Visual Inspection and Pre-checks

|

||||

| NOTE: At least 2 programmed keys/key fobs must be present to begin diagnosis of the RKE system. | ||||

| Q1 CHECK FOR THE CORRECT KEYS/KEY FOBS | ||||

Are the correct keys/key fobs present?

|

||||

| Q2 CHECK ALL KEYS/KEY FOBS FOR POOR RANGE PERFORMANCE | ||||

|

NOTE: Make sure the vehicle is in an open area with no other large metal objects near, such as other vehicles or steel buildings.

Do all keys/key fobs experience poor range?

|

||||

| Q3 CHECK THE KEY/KEY FOB BATTERY | ||||

|

NOTE: Do not clean off any grease from the battery terminals on the back surface of the circuit board.

Is the voltage greater than 2.5 volts?

|

||||

| Q4 CHECK THE PASSIVE KEY BATTERIES | ||||

|

NOTE: Do not clean off any grease from the battery terminals on the back surface of the circuit board.

Are the voltages greater than 2.5 volts?

|

||||

| Q5 CHECK THE LOCATION OF THE VEHICLE AND THE APPROACH ANGLES AROUND THE VEHICLE | ||||

Is the poor range performance consistent around the vehicle?

|

.jpg) PINPOINT TEST R : THE REMOTE START FEATURE IS INOPERATIVE

PINPOINT TEST R : THE REMOTE START FEATURE IS INOPERATIVE|

Normal Operation and Fault Conditions

REFER to: Handles, Locks, Latches and Entry Systems - Overview (501-14 Handles, Locks, Latches and Entry Systems, Description and Operation). Possible Sources

Visual Inspection and Pre-checks

|

||||||||||||||||||||||

| NOTE: This pinpoint test does not diagnose dealer installed remote start systems. | ||||||||||||||||||||||

| R1 CHECK THE REMOTE START FEATURE ENABLE/DISABLE SETTING | ||||||||||||||||||||||

Is the remote start feature enabled?

|

||||||||||||||||||||||

| R2 CHECK THE PARK DETECT SWITCH INPUT | ||||||||||||||||||||||

Does the PRNDL display correctly?

|

||||||||||||||||||||||

| R3 CHECK FOR BCM (BODY CONTROL MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | ||||||||||||||||||||||

Are any BCM Diagnostic Trouble Codes (DTCs) present?

|

||||||||||||||||||||||

| R4 CHECK FOR POWERTRAIN DIAGNOSTIC TROUBLE CODES (DTCS) | ||||||||||||||||||||||

Are any PCM Diagnostic Trouble Codes (DTCs) present?

|

||||||||||||||||||||||

| R5 CHECK THE RKE (REMOTE KEYLESS ENTRY) FUNCTIONALITY | ||||||||||||||||||||||

Do all the functions tested of the RKE transmitter operate (doors lock, doors unlock and liftgate latch unlock or power liftgate open)?

|

||||||||||||||||||||||

| R6 CHECK THE WAKE-UP CIRCUIT FOR VOLTAGE AT THE PCM (POWERTRAIN CONTROL MODULE) USING THE BCM (BODY CONTROL MODULE) PID (PARAMETER IDENTIFICATION) (PCM) WAKE-UP OUTPUT CONTROL (PCM_WKUP_CTRL) | ||||||||||||||||||||||

Is the voltage greater than 11 volts?

|

||||||||||||||||||||||

| R7 CHECK THE WAKE-UP CIRCUIT FOR AN OPEN | ||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

||||||||||||||||||||||

| R8 VERIFY THE REMOTE START FUNCTION IS INOPERATIVE | ||||||||||||||||||||||

Does the vehicle remotely start?

|

||||||||||||||||||||||

| R9 CHECK FOR CORRECT BCM (BODY CONTROL MODULE) OPERATION | ||||||||||||||||||||||

Is the concern still present?

|

.jpg) PINPOINT TEST S : A DOOR PASSIVE ENTRY FEATURE IS INOPERATIVE

PINPOINT TEST S : A DOOR PASSIVE ENTRY FEATURE IS INOPERATIVE|

Refer to Wiring Diagrams Cell 117 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Handles, Locks, Latches and Entry Systems - Overview (501-14 Handles, Locks, Latches and Entry Systems, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

Visual Inspection and Pre-checks

|

|||||||||||||||||||||||||||

| S1 CHECK THE DOOR LOCK OPERATION | |||||||||||||||||||||||||||

Do the doors lock and unlock?

|

|||||||||||||||||||||||||||

| S2 CHECK THE RKE (REMOTE KEYLESS ENTRY) OPERATION | |||||||||||||||||||||||||||

Do the doors lock and unlock?

|

|||||||||||||||||||||||||||

| S3 CHECK THE PASSIVE ENTRY OPERATION FROM BOTH FRONT DOORS | |||||||||||||||||||||||||||

Is the passive entry feature inoperative from both front doors?

|

|||||||||||||||||||||||||||

| S4 CHECK THE EXTERIOR DOOR HANDLE GROUND CIRCUIT FOR A SHORT TO VOLTAGE | |||||||||||||||||||||||||||

Is any voltage present?

|

|||||||||||||||||||||||||||

| S5 CHECK THE EXTERIOR DOOR HANDLE GROUND CIRCUIT FOR A SHORT TO GROUND | |||||||||||||||||||||||||||

Is the resistance greater than 10,000 ohms?

|

|||||||||||||||||||||||||||

| S6 CHECK THE EXTERIOR DOOR HANDLE GROUND CIRCUIT FOR AN OPEN (BOTH FRONT DOORS PASSIVE ENTRY INOPERATIVE) | |||||||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

|||||||||||||||||||||||||||

| S7 CHECK FOR VOLTAGE TO THE EXTERIOR DOOR HANDLE | |||||||||||||||||||||||||||

Is the voltage greater than 11 volts?

|

|||||||||||||||||||||||||||

| S8 CHECK THE EXTERIOR DOOR HANDLE VOLTAGE SUPPLY CIRCUIT FOR A SHORT TO GROUND | |||||||||||||||||||||||||||

Is the resistance greater than 10,000 ohms?

|

|||||||||||||||||||||||||||

| S9 CHECK THE EXTERIOR DOOR HANDLE VOLTAGE SUPPLY CIRCUIT FOR AN OPEN | |||||||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

|||||||||||||||||||||||||||

| S10 CHECK THE EXTERIOR DOOR HANDLE GROUND CIRCUIT FOR AN OPEN | |||||||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

|||||||||||||||||||||||||||

| S11 CHECK THE EXTERIOR DOOR HANDLE INTERNAL ANTENNA | |||||||||||||||||||||||||||

Is the resistance between 1 and 3 ohms?

|

|||||||||||||||||||||||||||

| S12 CHECK THE EXTERIOR DOOR HANDLE | |||||||||||||||||||||||||||

Does the keyless entry feature operate from the suspect door?

|

|||||||||||||||||||||||||||

| S13 CHECK THE EXTERIOR DOOR HANDLE ANTENNA CIRCUITS FOR A SHORT TO VOLTAGE | |||||||||||||||||||||||||||

Is any voltage present?

|

|||||||||||||||||||||||||||

| S14 CHECK THE EXTERIOR DOOR HANDLE ANTENNA CIRCUITS FOR A SHORT TO GROUND | |||||||||||||||||||||||||||

Are the resistances greater than 10,000 ohms?

|

|||||||||||||||||||||||||||

| S15 CHECK THE EXTERIOR DOOR HANDLE ANTENNA CIRCUITS FOR AN OPEN | |||||||||||||||||||||||||||

Are the resistances less than 3 ohms?

|

|||||||||||||||||||||||||||

| S16 CHECK FOR CORRECT BCM (BODY CONTROL MODULE) OPERATION | |||||||||||||||||||||||||||

Is the concern still present?

|

.jpg) PINPOINT TEST T : THE LIFTGATE PASSIVE ENTRY FEATURE IS INOPERATIVE

PINPOINT TEST T : THE LIFTGATE PASSIVE ENTRY FEATURE IS INOPERATIVE|

Refer to Wiring Diagrams Cell 117 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Handles, Locks, Latches and Entry Systems - Overview (501-14 Handles, Locks, Latches and Entry Systems, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

|||||||||||||

| T1 CHECK THE DOOR PASSIVE ENTRY FUNCTION | |||||||||||||

Does the door passive entry feature operate?

|

|||||||||||||

| T2 CHECK THE LIFTGATE RELEASE SWITCH INPUT | |||||||||||||

Does the liftgate latch release (manual liftgate) or power open (power liftgate)?

|

|||||||||||||

| T3 CHECK THE KEYLESS ENTRY REAR ANTENNA | |||||||||||||

Is the resistance between 1 and 3 ohms?

|

|||||||||||||

| T4 CHECK THE KEYLESS ENTRY REAR ANTENNA CIRCUITS FOR A SHORT TO VOLTAGE | |||||||||||||

Is any voltage present?

|

|||||||||||||

| T5 CHECK THE KEYLESS ENTRY REAR ANTENNA CIRCUITS FOR A SHORT TO GROUND | |||||||||||||

Are the resistances greater than 10,000 ohms?

|

|||||||||||||

| T6 CHECK THE KEYLESS ENTRY REAR ANTENNA CIRCUITS FOR AN OPEN | |||||||||||||

Are the resistances less than 3 ohms?

|

|||||||||||||

| T7 CHECK FOR CORRECT BCM (BODY CONTROL MODULE) OPERATION | |||||||||||||

Is the concern still present?

|

.jpg) PINPOINT TEST U : U0258:87 OR U1A00:00

PINPOINT TEST U : U0258:87 OR U1A00:00|

Refer to Wiring Diagrams Cell 117 for schematic and connector information. Normal Operation and Fault Conditions The RTM communicates with the BCM over a LIN-based circuit and, when the network is awake, over the CAN. DTC Fault Trigger Conditions

Possible Sources

|

||||||||||

| U1 CHECK IF THE RTM (RADIO TRANSCEIVER MODULE) AND THE BCM (BODY CONTROL MODULE) PASS THE NETWORK TEST | ||||||||||

Does the RTM and the BCM pass the network test?

|

||||||||||

| U2 CHECK THE LIN (LOCAL INTERCONNECT NETWORK) CIRCUIT FOR A SHORT TO VOLTAGE | ||||||||||

Is any voltage present?

|

||||||||||

| U3 CHECK THE LIN (LOCAL INTERCONNECT NETWORK) CIRCUIT FOR A SHORT TO GROUND | ||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||

| U4 CHECK THE LIN (LOCAL INTERCONNECT NETWORK) CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| U5 CHECK FOR CORRECT RTM (RADIO TRANSCEIVER MODULE) OPERATION | ||||||||||

Is the concern still present?

|

.jpg) PINPOINT TEST V : U0140:00

PINPOINT TEST V : U0140:00|

Normal Operation and Fault Conditions The DDM/ PDM communicates with the BCM over the CAN. If the DDM/ PDM does not receive messages from the BCM, features such as the puddle lamps, exterior mirror turn signal and door switch illumination can be inoperative. DTC Fault Trigger Conditions

Possible Sources

|

|||||||||

| V1 VERIFY THE CUSTOMER CONCERN | |||||||||

Is an observable symptom present?

|

|||||||||

| V2 CHECK THE COMMUNICATION NETWORK | |||||||||

Does the BCM pass the network test?

|

|||||||||

| V3 CHECK FOR BCM (BODY CONTROL MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||

Are any voltage related Diagnostic Trouble Codes (DTCs) present?

|

|||||||||

| V4 RECHECK THE DDM (DRIVER DOOR MODULE) OR PDM (PASSENGER DOOR MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||

|

NOTE: If new modules were installed prior to the DTC being set, the module configuration may be incorrectly set during PMI or the PMI may not have been performed.

Is DTC U0140:00 still present?

|

|||||||||

| V5 CHECK FOR DTC (DIAGNOSTIC TROUBLE CODE) U0140 SET IN OTHER MODULES | |||||||||

Is DTC U0140 set in other modules?

|

.jpg) PINPOINT TEST W : U0208:00

PINPOINT TEST W : U0208:00|

Normal Operation and Fault Conditions The DDM/ PDM communicate with the DSM over the CAN. If the DDM/ PDM does not receive messages from the DSM, features such as the memory mirror position can be inoperative. DTC Fault Trigger Conditions

Possible Sources

|

|||||||||

| W1 VERIFY THE CUSTOMER CONCERN | |||||||||

Is an observable symptom present?

|

|||||||||

| W2 CHECK THE COMMUNICATION NETWORK | |||||||||

Does the DSM pass the network test?

|

|||||||||

| W3 CHECK FOR DSM (DRIVER FRONT SEAT MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||

Are any voltage related Diagnostic Trouble Codes (DTCs) present?

|

|||||||||

| W4 RECHECK THE DDM (DRIVER DOOR MODULE) OR PDM (PASSENGER DOOR MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||

|

NOTE: If new modules were installed prior to the DTC being set, the module configuration may be incorrectly set during PMI or the PMI may not have been performed.

Is DTC U0208:00 still present?

|

|||||||||

| W5 CHECK FOR DTC (DIAGNOSTIC TROUBLE CODE) U0208 SET IN OTHER MODULES | |||||||||

Is DTC U0208 set in other modules?

|

.jpg) PINPOINT TEST X : U0232:00

PINPOINT TEST X : U0232:00|

Normal Operation and Fault Conditions The DDM/ PDM communicates with the SODL over the CAN. If the DDM/ PDMdoes not receive messages from the SODL, the side obstacle detection feature can be inoperative for the left side. DTC Fault Trigger Conditions

Possible Sources

|

|||||||||

| X1 VERIFY THE CUSTOMER CONCERN | |||||||||

Is an observable symptom present?

|

|||||||||

| X2 CHECK THE COMMUNICATION NETWORK | |||||||||

Does the SODL pass the network test?

|

|||||||||

| X3 CHECK FOR SODL (SIDE OBSTACLE DETECTION CONTROL MODULE LH) DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||

Are any voltage related Diagnostic Trouble Codes (DTCs) present?

|

|||||||||

| X4 RECHECK THE DDM (DRIVER DOOR MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||

|

NOTE: If new modules were installed prior to the DTC being set, the module configuration may be incorrectly set during PMI or the PMI may not have been performed.

Is DTC U0232:00 still present?

|

|||||||||

| X5 CHECK FOR DTC (DIAGNOSTIC TROUBLE CODE) U0232 SET IN OTHER MODULES | |||||||||

Is DTC U0232 set in other modules?

|

.jpg) PINPOINT TEST Y : U0233:00

PINPOINT TEST Y : U0233:00|

Normal Operation and Fault Conditions The DDM/ PDM communicates with the SODR over the CAN. If the DDM/ PDM does not receive messages from the SODR, the side obstacle detection feature can be inoperative for the right side. DTC Fault Trigger Conditions

Possible Sources

|

|||||||||

| Y1 VERIFY THE CUSTOMER CONCERN | |||||||||

Is an observable symptom present?

|

|||||||||

| Y2 CHECK THE COMMUNICATION NETWORK | |||||||||

Does the SODR pass the network test?

|

|||||||||

| Y3 CHECK FOR SODR (SIDE OBSTACLE DETECTION CONTROL MODULE RH) DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||

Are any voltage related Diagnostic Trouble Codes (DTCs) present?

|

|||||||||

| Y4 RECHECK THE DDM (DRIVER DOOR MODULE) / PDM (PASSENGER DOOR MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||

|

NOTE: If new modules were installed prior to the DTC being set, the module configuration may be incorrectly set during PMI or the PMI may not have been performed.

Is DTC U0233:00 still present?

|

|||||||||

| Y5 CHECK FOR DTC (DIAGNOSTIC TROUBLE CODE) U0233 SET IN OTHER MODULES | |||||||||

Is DTC U0233 set in other modules?

|

.jpg) PINPOINT TEST Z : P1594 OR P1595

PINPOINT TEST Z : P1594 OR P1595|

Normal Operation and Fault Conditions When the BCM receives a request to remote start the vehicle, it first checks to make sure conditions exist to allow it to start (for example, the hood and doors closed, vehicle in PARK, no powertrain concerns). If the required conditions are correct, the BCM starts the vehicle and allows it to run for a predetermined amount of time, determined by the setting selected from the message center. DTC Fault Trigger Conditions

Possible Sources

|

|||||||||

| Z1 CHECK FOR OTHER PCM (POWERTRAIN CONTROL MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||

Are any PCM Diagnostic Trouble Codes (DTCs) besides P1594:00 or P1595:00 present?

|

|||||||||

| Z2 CHECK FOR BCM (BODY CONTROL MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||

Are any BCM Diagnostic Trouble Codes (DTCs) present?

|

.jpg) PINPOINT TEST AA : U0164:00

PINPOINT TEST AA : U0164:00|

Normal Operation and Fault Conditions The DDM/ PDM communicates with the HVAC module over the CAN. If the DDM/ PDM does not receive messages from the HVAC module, features such as the mirror defrost can be inoperative. DTC Fault Trigger Conditions

Possible Sources

|

|||||||||

| AA1 VERIFY THE CUSTOMER CONCERN | |||||||||

Is an observable symptom present?

|

|||||||||

| AA2 CHECK THE COMMUNICATION NETWORK | |||||||||

Does the HVAC module pass the network test?

|

|||||||||

| AA3 CHECK FOR BCM (BODY CONTROL MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||

Are any voltage related Diagnostic Trouble Codes (DTCs) present?

|

|||||||||

| AA4 RECHECK THE DDM (DRIVER DOOR MODULE) OR PDM (PASSENGER DOOR MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||

|

NOTE: If new modules were installed prior to the DTC being set, the module configuration may be incorrectly set during PMI or the PMI may not have been performed.

Is DTC U0164:00 still present?

|

|||||||||

| AA5 CHECK FOR DTC (DIAGNOSTIC TROUBLE CODE) U0164 SET IN OTHER MODULES | |||||||||

Is DTC U0164 set in other modules?

|

.jpg) PINPOINT TEST AB : U0294:00

PINPOINT TEST AB : U0294:00|

Normal Operation and Fault Conditions The DDM/ PDM communicates with the PCM over the CAN. If the DDM/ PDM does not receive messages from the PCM, the window inhibit feature during a start/stop event can be inoperative. DTC Fault Trigger Conditions

Possible Sources

|

|||||||||

| AB1 VERIFY THE CUSTOMER CONCERN | |||||||||

Is an observable symptom present?

|

|||||||||

| AB2 CHECK THE COMMUNICATION NETWORK | |||||||||

Does the PCM pass the network test?

|

|||||||||

| AB3 CHECK FOR BCM (BODY CONTROL MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||

Are any voltage related Diagnostic Trouble Codes (DTCs) present?

|

|||||||||

| AB4 RECHECK THE DDM (DRIVER DOOR MODULE) OR PDM (PASSENGER DOOR MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||

|

NOTE: If new modules were installed prior to the DTC being set, the module configuration may be incorrectly set during PMI or the PMI may not have been performed.

Is DTC U0294:00 still present?

|

|||||||||

| AB5 CHECK FOR DTC (DIAGNOSTIC TROUBLE CODE) U0294 SET IN OTHER MODULES | |||||||||

Is DTC U0294 set in other modules?

|

.jpg) PINPOINT

TEST AC :

U2100:00

PINPOINT

TEST AC :

U2100:00|

Normal Operation and Fault Conditions The DDM/ PDM is able to communicate with others modules after a PMI is complete. DTC Fault Trigger Conditions

Possible Sources

|

|||||||||

| AC1 CHECK DDM (DRIVER DOOR MODULE) / PDM (PASSENGER DOOR MODULE) DIAGNOSTIC TROUBLE CODES (DTC'S) | |||||||||

Are there any other Diagnostic Trouble Codes (DTC's) Present?

|

.jpg) PINPOINT TEST AD : THE MANUAL LIFTGATE DOES NOT LATCH

PINPOINT TEST AD : THE MANUAL LIFTGATE DOES NOT LATCH|

Refer to Wiring Diagrams Cell 117 for schematic and connector information. Refer to Wiring Diagrams Cell 96 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Handles, Locks, Latches and Entry Systems - Overview (501-14 Handles, Locks, Latches and Entry Systems, Description and Operation). Possible Sources

Visual Inspection and Pre-checks

|

||||

| AD1 DISCONNECT THE LIFTGATE LATCH. CHECK THE OPERATION OF THE LATCH. | ||||

Does the latch fully latch after 2 clicks?

|

.jpg) PINPOINT TEST AE : THE FUEL FILLER DOOR LOCK IS INOPERATIVE

PINPOINT TEST AE : THE FUEL FILLER DOOR LOCK IS INOPERATIVE|

Refer to Wiring Diagrams Cell 117 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Handles, Locks, Latches and Entry Systems - Overview (501-14 Handles, Locks, Latches and Entry Systems, Description and Operation). Possible Sources

Visual Inspection and Pre-checks

|

||||||||||

| NOTICE: Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may damage the connector. | ||||||||||

| AE1 CHECK THE ELECTRONIC DRIVER DOOR LOCK OPERATION | ||||||||||

Does the driver door lock indicator operate correctly?

|

||||||||||

| AE2 CHECK THE LOCK CIRCUIT FOR AN OPEN | ||||||||||

|

NOTICE: The following step uses a test lamp to simulate normal circuit loads. Use only a Rotunda Test Lamp (SGT27000) or 250-300mA incandescent bulb test lamp. To avoid connector terminal damage, use the Rotunda Flex Probe kit for the test lamp probe connection to the vehicle. Do not use the test lamp probe directly on any connector.

Does the test lamp momentarily illuminate?

|

||||||||||

| AE3 CHECK THE UNLOCK CIRCUIT FOR AN OPEN | ||||||||||

|

NOTICE: The following step uses a test lamp to simulate normal circuit loads. Use only a Rotunda Test Lamp (SGT27000) or 250-300mA incandescent bulb test lamp. To avoid connector terminal damage, use the Rotunda Flex Probe kit for the test lamp probe connection to the vehicle. Do not use the test lamp probe directly on any connector.

Does the test lamp momentarily illuminate?

|

.jpg) PINPOINT TEST AF : U3003:16

PINPOINT TEST AF : U3003:16|

Refer to Wiring Diagrams Cell 117 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Handles, Locks, Latches and Entry Systems - Overview (501-14 Handles, Locks, Latches and Entry Systems, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

||||||||||||||||

| NOTE: Low vehicle battery state of charge will disable the passive entry feature from all the doors except the driver’s door. | ||||||||||||||||

| AF1 RECHECK FOR DTC (DIAGNOSTIC TROUBLE CODE) U3003:16 | ||||||||||||||||

Is DTC U3003:16 still present?

|

||||||||||||||||

| AF2 CHECK FOR CHARGING SYSTEM DIAGNOSTIC TROUBLE CODES (DTCS) IN THE PCM (POWERTRAIN CONTROL MODULE) | ||||||||||||||||

Are any voltage-related Diagnostic Trouble Codes (DTCs) set in the PCM?

|

||||||||||||||||

| AF3 CHECK THE BATTERY CONDITION AND STATE OF CHARGE | ||||||||||||||||

Is the battery OK and fully charged?

|

||||||||||||||||

| AF4 CHECK THE SUSPECT MODULE VOLTAGE SUPPLY | ||||||||||||||||

Is the voltage within 0.2 volts of the recorded battery voltage?

|

||||||||||||||||

| AF5 CHECK THE SUSPECT MODULE GROUND CIRCUIT | ||||||||||||||||

Is the DDM/ PDM voltage greater than 11 volts?

|

||||||||||||||||

| AF6 CHECK FOR CORRECT DDM (DRIVER DOOR MODULE) / PDM (PASSENGER DOOR MODULE) OPERATION | ||||||||||||||||

Is the concern still present?

|

.jpg) PINPOINT TEST AG : U3003:17

PINPOINT TEST AG : U3003:17|

Refer to Wiring Diagrams Cell 117 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Handles, Locks, Latches and Entry Systems - Overview (501-14 Handles, Locks, Latches and Entry Systems, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

|||||||||

| AG1 RECHECK FOR DTC (DIAGNOSTIC TROUBLE CODE) U3003:17 | |||||||||

Is DTC U3003:17 present?

|

|||||||||

| AG2 CHECK FOR HIGH VOLTAGE DIAGNOSTIC TROUBLE CODES (DTCS) SET IN MULTIPLE MODULES | |||||||||

Are high voltage Diagnostic Trouble Codes (DTCs) such as B1676, P0563, or U3003:17 set in more than one module?

|

|||||||||

| AG3 CHECK THE BATTERY VOLTAGE | |||||||||

Does the battery voltage rise to 15.5 volts or higher?

|

|||||||||

| AG4 CHECK FOR CORRECT DDM (DRIVER DOOR MODULE) / PDM (PASSENGER DOOR MODULE) OPERATION | |||||||||

Is the concern still present?

|

.jpg) PINPOINT

TEST AH :

U2200:00, U3000:49

PINPOINT

TEST AH :

U2200:00, U3000:49|

Normal Operation and Fault Conditions

REFER to: Handles, Locks, Latches and Entry Systems - System Operation and Component Description (501-14 Handles, Locks, Latches and Entry Systems, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

|||||||||||||||

| AH1 CHECK DDM (DRIVER DOOR MODULE) / PDM (PASSENGER DOOR MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||||||||

Is diagnostic code U2200:00 or U3000:49 present?

|

.jpg) PINPOINT TEST AI : THE FUEL FILLER DOOR RELEASE IS INOPERATIVE (HYBRID VEHICLES)

PINPOINT TEST AI : THE FUEL FILLER DOOR RELEASE IS INOPERATIVE (HYBRID VEHICLES)|

Refer to Wiring Diagrams Cell 116 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Handles, Locks, Latches and Entry Systems - System Operation and Component Description (501-14 Handles, Locks, Latches and Entry Systems, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

Visual Inspection and Pre-checks

|

||||||||||||||||||

| NOTICE: Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may damage the connector. | ||||||||||||||||||

| AI1 CHECK FOR A MECHANICAL FAILURE | ||||||||||||||||||

Does the fuel filler door latch release?

|

||||||||||||||||||

| AI2 CHECK THE PCM (POWERTRAIN CONTROL MODULE) THE CUSTOMER IS REQUESTING OR HAS RECENTLY REQUESTED TO OPEN OR UNLOCK THE FUEL FILL DOOR (FUELDR_REQ) PID (PARAMETER IDENTIFICATION) | ||||||||||||||||||

Does the PID correspond with the fuel filler door release button press?

|

||||||||||||||||||

| AI3 BYPASS THE FUEL FILLER DOOR RELEASE SWITCH | ||||||||||||||||||

Does the fuel filler door latch release?

|

||||||||||||||||||

| AI4 CHECK THE FUEL FILLER RELEASE SWITCH GROUND CIRCUIT FOR AN OPEN | ||||||||||||||||||

Does the fuel filler door latch release?

|

||||||||||||||||||

| AI5 CHECK THE FUEL FILLER RELEASE SWITCH INPUT CIRCUIT FOR A SHORT TO GROUND | ||||||||||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||||||||||

| AI6 CHECK THE FUEL FILLER RELEASE SWITCH RETURN CIRCUIT FOR A SHORT TO VOLTAGE | ||||||||||||||||||

Is any voltage present?

|

||||||||||||||||||

| AI7 CHECK THE FUEL FILLER RELEASE SWITCH INPUT AND RETURN CIRCUITS FOR AN OPEN | ||||||||||||||||||

Are the resistances less than 3 ohms?

|

||||||||||||||||||

| AI8 CHECK THE FUEL FILLER DOOR RELEASE USING THE PCM (POWERTRAIN CONTROL MODULE) FUEL FILL DOOR UNLOCK CONTROL OUTPUT IS COMMANDED TO ENABLE STATE (FUELDR_UNLOCK) PID (PARAMETER IDENTIFICATION) | ||||||||||||||||||

Does the fuel filler door latch release?

|

||||||||||||||||||

| AI9 CHECK THE FUEL FILLER DOOR SOLENOID VOLTAGE SUPPLY CIRCUIT FOR AN OPEN | ||||||||||||||||||

|

NOTICE: The following step uses a test lamp to simulate normal circuit loads. Use only a Rotunda Test Lamp (SGT27000) or 250-300mA incandescent bulb test lamp. To avoid connector terminal damage, use the Rotunda Flex Probe kit for the test lamp probe connection to the vehicle. Do not use the test lamp probe directly on any connector.

Does the test lamp illuminate?

|

||||||||||||||||||

| AI10 CHECK THE FUEL FILLER DOOR RELEASE RELAY OUTPUT USING THE PCM (POWERTRAIN CONTROL MODULE) FUEL FILL DOOR UNLOCK CONTROL OUTPUT IS COMMANDED TO ENABLE STATE (FUELDR_UNLOCK) PID (PARAMETER IDENTIFICATION) | ||||||||||||||||||

|

NOTICE: The following step uses a test lamp to simulate normal circuit loads. Use only a Rotunda Test Lamp (SGT27000) or 250-300mA incandescent bulb test lamp. To avoid connector terminal damage, use the Rotunda Flex Probe kit for the test lamp probe connection to the vehicle. Do not use the test lamp probe directly on any connector.

Does the test lamp momentarily illuminate?

|

||||||||||||||||||

| AI11 CHECK THE FUEL FILLER DOOR SOLENOID GROUND CIRCUIT FOR AN OPEN | ||||||||||||||||||

Is the resistance less than 3 ohms?

|

||||||||||||||||||

| AI12 CHECK THE PCM (POWERTRAIN CONTROL MODULE) THE FUEL FILL DOOR POSITION SENSOR/SWITCH CIRCUIT INPUT (FUELDR_POS_SW) PID (PARAMETER IDENTIFICATION) | ||||||||||||||||||

Does the PID indicate Closed with the fuel filler door closed and Open after the fuel filler door latch is released?

|

||||||||||||||||||

| AI13 CHECK FOR CORRECT PCM (POWERTRAIN CONTROL MODULE) OPERATION | ||||||||||||||||||

Is the concern still present?

|

.jpg) PINPOINT TEST AJ : THE FUEL FILLER DOOR DOES NOT LATCH (HYBRID VEHICLES)

PINPOINT TEST AJ : THE FUEL FILLER DOOR DOES NOT LATCH (HYBRID VEHICLES)|

Refer to Wiring Diagrams Cell 116 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Handles, Locks, Latches and Entry Systems - System Operation and Component Description (501-14 Handles, Locks, Latches and Entry Systems, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

Visual Inspection and Pre-checks

|

||||||||||

| NOTICE: Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may damage the connector. | ||||||||||

| AJ1 CHECK FOR A MECHANICAL FAILURE | ||||||||||

Is the manual fuel filler door release cable binding or is there any damage noted with the fuel filler door latch?

|

||||||||||

| AJ2 CHECK THE FUEL FILLER DOOR RELEASE CONTROL | ||||||||||

Does the fuel filler door latch?

|

||||||||||

| AJ3 CHECK THE PCM (POWERTRAIN CONTROL MODULE) FUEL FILLER DOOR RELEASE CONTROL CIRCUIT FOR A SHORT TO GROUND | ||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||

| AJ4 CHECK FOR CORRECT PCM (POWERTRAIN CONTROL MODULE) OPERATION | ||||||||||

Is the concern still present?

|

.jpg) PINPOINT TEST AK : P04B5, P04BA

PINPOINT TEST AK : P04B5, P04BA|

Refer to Wiring Diagrams Cell 116 for schematic and connector information. Normal Operation and Fault Conditions The PCM monitors the fuel filler door ajar switch and sets a DTC if it detects a failure of the fuel filler door ajar input based on conditions after a refueling event. If the fuel filler door is not fully closed after a refueling event, or the fuel filler door is open from erroneously pressing the fuel door release button, a message displays during the third drive cycle to indicate the fuel filler door is not closed and a DTC sets. DTC Fault Trigger Conditions

Possible Sources

|

|||||||||||||

| NOTICE: Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may damage the connector. | |||||||||||||

| AK1 CHECK FOR MECHANICAL DAMAGE | |||||||||||||

Is any damage present?

|

|||||||||||||

| AK2 CHECK THE PCM (POWERTRAIN CONTROL MODULE) THE CUSTOMER IS REQUESTING OR HAS RECENTLY REQUESTED TO OPEN OR UNLOCK THE FUEL FILL DOOR (FUELDR_REQ) PID (PARAMETER IDENTIFICATION) | |||||||||||||

Does the PID momentarily indicate Yes?

|

|||||||||||||

| AK3 CHECK THE FUEL FILLER DOOR RELEASE USING THE PCM (POWERTRAIN CONTROL MODULE) FUEL FILL DOOR UNLOCK CONTROL OUTPUT IS COMMANDED TO ENABLE STATE (FUELDR_UNLOCK) PID (PARAMETER IDENTIFICATION) | |||||||||||||

Does the fuel filler door latch release?

|

|||||||||||||

| AK4 CHECK THE PCM (POWERTRAIN CONTROL MODULE) THE FUEL FILL DOOR POSITION SENSOR/SWITCH CIRCUIT INPUT (FUELDR_POS_SW) PID (PARAMETER IDENTIFICATION) | |||||||||||||

Does the PID indicate Closed with the fuel filler door closed and Open after the fuel filler door latch is released?

|

|||||||||||||

| AK5 CHECK THE FUEL FILLER DOOR AJAR CIRCUITS FOR A SHORT TO VOLTAGE | |||||||||||||

|

NOTE: The fuel filler door electrical connectors can be accessed through an opening in the left side sheet metal inside luggage compartment area.

Is any voltage present?

|

|||||||||||||

| AK6 CHECK THE FUEL FILLER DOOR AJAR CIRCUITS FOR A SHORT TO GROUND | |||||||||||||

Are the resistances greater than 10,000 ohms?

|

|||||||||||||

| AK7 CHECK THE FUEL FILLER DOOR AJAR CIRCUITS FOR AN OPEN | |||||||||||||

Are the resistances less than 3 ohms?

|

|||||||||||||

| AK8 CHECK FOR CORRECT PCM (POWERTRAIN CONTROL MODULE) OPERATION | |||||||||||||

Is the concern still present?

|

Description and Operation - Handles, Locks, Latches and Entry Systems - System Operation and Component Description

Description and Operation - Handles, Locks, Latches and Entry Systems - System Operation and Component Description

System Operation

System Diagram

Item

Description

1

Exterior Door Handles

2

Antenna

3

BCM

4

Liftgate Release Switch

5

Passive Key (if equipped) (exc..

General Procedures - Door Latch Lubrication

General Procedures - Door Latch Lubrication

Special Tool(s) /

General Equipment

Flat-Bladed Screwdriver

Materials

Name

Specification

Motorcraft® Multi-Purpose Grease SprayXL-5-A

ESB-M1C93-B

Activation

NOTE:

..

Other information:

Ford Explorer 2020-2025 Service Manual: General Procedures - Elevation System Check

Check Turn the ignition ON, engine OFF. Set the parking brake. Place the gearshift in REVERSE (R) for rear parking aid sensors. Place the gearshift in DRIVE (D) for front parking aid sensors...

Ford Explorer 2020-2025 Service Manual: Diagnosis and Testing - E Clutch

Symptom Chart E Clutch For E clutch operation, REFER to: E Clutch (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Description and Operation). E Clutch Condition Possible Sources Action E clutch does not apply SSE mechanically stuck OFF INSTALL a new solenoid...

Categories

- Manuals Home

- 6th Generation Explorer Owners Manual

- 6th Generation Explorer Service Manual

- Auxiliary Power Points

- Fuel Filler Funnel Location & Running Out of Fuel

- Engine

- New on site

- Most important about car

Gauges

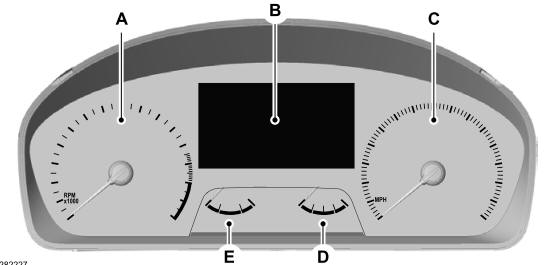

4 Inch Display

A - Tachometer.

B - Information display.

C - Speedometer.

D - Fuel gauge.

E - Engine coolant temperature gauge.

.jpg) PINPOINT TEST A : HARD TO OPEN OR CLOSE A DOOR FROM EITHER DOOR HANDLE

PINPOINT TEST A : HARD TO OPEN OR CLOSE A DOOR FROM EITHER DOOR HANDLE.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg) C4332, pin 1, component side

C4332, pin 1, component side

.png) Internet Explorer version 11 or greater is required to perform this Pinpoint Test.

Internet Explorer version 11 or greater is required to perform this Pinpoint Test.