Ford Explorer: Driveshaft / Disassembly and Assembly - Driveshaft Universal Joint

Special Tool(s) / General Equipment

.jpg) |

205-086

(T74P-4635-C)

Installer/Remover, C-Frame and Screw |

Materials

| Name | Specification |

|---|---|

| Motorcraft® Premium Long-Life Grease XG-1-E1 |

ESA-M1C75-B |

DISASSEMBLY

NOTICE: Do not, under any circumstance, clamp the driveshaft assembly in the jaws of a vise or similar holding fixture. Denting or localized fracturing may result, causing driveshaft failure during vehicle operation.

NOTE: This procedure is intended to be used for all U-joints with snap ring retainers.

-

Remove the front driveshaft.

Refer to: Front Driveshaft (205-01 Driveshaft, Removal and Installation).

-

NOTE: Spline stud yoke shaft U-joint shown, others similar.

Remove and discard the snap rings.

.jpg) |

-

NOTE: Spline stud yoke shaft U-joint shown, others similar.

Using the special tool, press the U-joint bearing cups out of the spline stud yoke shaft and remove the spline stud yoke shaft.

Use Special Service Tool: 205-086 (T74P-4635-C) Installer/Remover, C-Frame and Screw.

.jpg) |

-

Using the special tool, press the U-joint bearing cups

out of the driveshaft yoke. Remove and discard the U-joint.

Use Special Service Tool: 205-086 (T74P-4635-C) Installer/Remover, C-Frame and Screw.

.jpg) |

-

NOTE: Inspect the bearing cup bores and retaining ring grooves. Remove any rust or other surface irregularities.

NOTE: Spline stud yoke shaft U-joint shown, others similar.

Clean and inspect the U-joint bearing cup surfaces.

.jpg) |

ASSEMBLY

NOTE: Install the U-joint kits as complete assemblies only. Do not mix components from other U-joint kits.

-

Lubricate the U-joint bearing cup bores.

Material: Motorcraft® Premium Long-Life Grease / XG-1-E1 (ESA-M1C75-B)

.jpg) |

-

NOTE: The bearing cup needle bearings need to be in the correct position.

Using the special tool, install the new U-joint spider and bearing cups into the driveshaft yoke.

Use Special Service Tool: 205-086 (T74P-4635-C) Installer/Remover, C-Frame and Screw.

.jpg) |

-

Install the new bearing cup snap rings into the driveshaft yoke grooves.

.jpg) |

-

NOTE: Front driveshaft to spline stud yoke shaft U-joint shown, others similar.

Using the special tool, install the new bearing cups on the opposite side of the spline stud yoke shaft.

Use Special Service Tool: 205-086 (T74P-4635-C) Installer/Remover, C-Frame and Screw.

.jpg) |

-

Install the new bearing cup snap rings into the spline stud yoke shaft grooves.

.jpg) |

-

Rotate the spline stud yoke shaft to make sure the

U-joints are free to rotate easily, without binding, before installing

the driveshaft.

.jpg) |

-

Install the front driveshaft.

Refer to: Front Driveshaft (205-01 Driveshaft, Removal and Installation).

Disassembly and Assembly - Driveshaft Center Bearing

Disassembly and Assembly - Driveshaft Center Bearing

Special Tool(s) /

General Equipment

Hydraulic Press

Bearing Separator

Materials

Name

Specification

Motorcraft® Premium Long-Life GreaseXG-1-E1

ESA-M1C75-B

DISASS..

Other information:

Ford Explorer 2020-2025 Service Manual: Removal and Installation - Ignition Switch - Vehicles With: Keyless Vehicle System

Removal NOTE: Removal steps in this procedure may contain installation details. Release the clips and remove the trim panel. Remove the retainers. Torque: 22 lb.in (2.5 Nm) Release the clips and and position the instrument panel center trim panel aside...

Ford Explorer 2020-2025 Service Manual: Removal and Installation - Oil Pump

Special Tool(s) / General Equipment 100-002 (TOOL-4201-C) Holding Fixture with Dial Indicator Gauge 303-1685Alignment Tool, Camshaft 303-1688Preload Tool, Balance Shaft 303-507Timing Peg, Crankshaft TDCTKIT-2001N-FLMTKIT-2001N-ROW Removal Remove the oil pan...

Categories

- Manuals Home

- 6th Generation Explorer Owners Manual

- 6th Generation Explorer Service Manual

- Interior Trim and Ornamentation

- Body and Paint

- Automatic Transmission - 10-Speed Automatic Transmission – 10R60

- New on site

- Most important about car

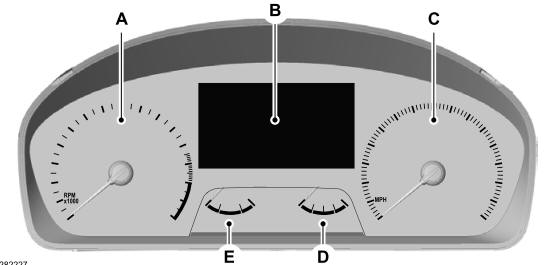

Gauges

4 Inch Display

A - Tachometer.

B - Information display.

C - Speedometer.

D - Fuel gauge.

E - Engine coolant temperature gauge.