Ford Explorer: Front Seats / Description and Operation - Front Seats - System Operation and Component Description

System Operation

System Diagram - Memory Seat

.jpg)

| Item | Description |

|---|---|

| 1 | HS-CAN1 |

| 2 | PCM |

| 3 | BCM |

| 4 | HS-CAN1 |

| 5 | Ignition Switch |

| 6 | GWM |

| 7 | Memory Set Switch |

| 8 | Driver Seat Control Switch |

| 9 | MS-CAN |

| 10 | DSM |

| 11 | MS-CAN |

| 12 | DDM |

| 13 | Memory Power Seat Motors |

https://magicaliptv.com/iptv-free-trials/

Network Message Chart - Memory Seat

DSM Network Input Messages

| Broadcast Message | Originating Module | Message Purpose |

|---|---|---|

| Key-in-ignition status | BCM | Provides the ignition status for the easy entry/exit feature. |

| Personality recall | BCM | When the personality recall command is received from the BCM, the DSM stores or recalls the associated memory seat position (1, 2 or 3). If a RKE transmitter has been programmed to a memory position, this input recalls the associated memory seat position. |

| Memory seat switch status | DDM | When the memory set switch (1, 2 or 3) is activated, the DDM sends this message to the DSM, which then stores or recalls the associated memory seat position. |

System Diagram - Heated/Ventilated Seats

.jpg)

| Item | Description |

|---|---|

| 1 | MS-CAN |

| 2 | SCME |

| 3 | HVAC module |

| 4 | Cushion and Backrest Blower Motors |

| 5 | Driver Seat |

| 6 | Cushion Heater Mat |

| 7 | Cushion Temp Sensor |

| 8 | Backrest Heater Mat |

| 9 | Passenger Seat |

| 10 | Cushion and Backrest Blower Motors |

| 11 | Cushion Temp Sensor |

| 12 | Cushion Heater Mat |

| 13 | Backrest Heater Mat |

Network Message Chart - Heated/Ventilated Seats

SCME Network Input Messages

| Broadcast Message | Originating Module | Message Purpose |

|---|---|---|

| Climate control requests | HVAC module | Contains the heated/ventilated seat request information. |

HVAC Module Network Input Messages

| Broadcast Message | Originating Module | Message Purpose |

|---|---|---|

| Climate control button status | SCME | The SCME provides this message to the HVAC module for the purpose of updating the displayed status of the heated/ventilated seat buttons on the HVAC module. |

System Diagram - Multi-Contour Front Seats

.jpg)

| Item | Description |

|---|---|

| 1 | FDIM |

| 2 | APIM |

| 3 | HS-CAN1 |

| 4 | GWM |

| 5 | MS-CAN |

| 6 | Seat Control Switch |

| 7 | SCMG/ SCMH |

| 8 | Front Seat Power Lumbar Assembly |

| 9 | Front Seat Cushion Adjuster |

Network Message Chart - Multi-Contour Front Seats

FDIM Network Input Messages

| Broadcast Message | Originating Module | Message Purpose |

|---|---|---|

| Multi-contour seat switch status | SCMG/ SCMH | The SCMG/ SCMH provides this message to the FDIM for the purpose of updating the displayed status of the multi-contour seat buttons on the FDIM (touchscreen). |

| Driver/passenger multi-contour seat position data | SCMG/ SCMH | The SCMG and SCMH provide this message to the FDIM for the purpose of updating the displayed pressure of the multi-contour seat bladders and bolster pairs on the FDIM (touchscreen). |

SCMG/ SCMH Network Input Messages

| Broadcast Message | Originating Module | Message Purpose |

|---|---|---|

| Multi-contour seat request | FDIM | The multi-contour seat request message contains the requested multi-contour function(s) from the touchscreen. |

Memory Seat Operation

The driver seat control switch provides a voltage signal to the DSM when activated. This voltage signal causes the DSM to power the appropriate motor until the input is removed. The motor circuits are normally grounded through the DSM. The DSM internally switches the appropriate circuit from ground to voltage to operate the motors.

As the seat is adjusted, the DSM monitors fluctuations of the motor current (ripple count for DC (direct current) motors) to determine the current seat position. The DSM removes voltage from the motor upon termination of the seat control switch input or if the DSM does not detect movement from the motor.

DSM Hard Stop/Soft Stop

A hard stop occurs when one of the memory front seat track or front seat backrest axes physically reach the end of travel and can go no further. A soft stop occurs when the seat stops before it physically reaches the end of travel. The hard stop is set by seat design and cannot be changed or adjusted. The soft stop is set by the DSM. The front seat track axes are forward/rearward, front up/down and rear up/down. The backrest axis is recline forward/backward. To prevent unnecessary stress on the seat and motors, the DSM sets soft stop positions, 2 for each moving axis. The DSM uses a preset distance from the hard stop to determine where the soft stop occurs. When an axis reaches the hard stop and the switch is held for approximately one second, the DSM briefly reverses direction and establishes the soft stop for that axis in that direction. The DSM uses this back up strategy to check sensor integrity any time movement has stopped prematurely due to a sensor failure or obstruction.

Easy Entry/Exit

The easy entry/exit feature is a function of the DSM that moves the driver seat rearward approximately 50.8 mm (2 in) (unless seat is already positioned at or near the end of travel) when the ignition is turned off. The DSM receives ignition off status over the MS-CAN and operates the driver seat rearward. The DSM cancels this operation if the function is disabled or a valid input command is received from the driver seat control switch, memory set switch or exterior mirror control switch.

The DSM records the current seat positions before operating the seat for an easy exit operation. During easy entry operation (when the ignition is turned on), the seat is returned to the recorded seat position prior to the easy exit operation. Easy entry operation is cancelled if a valid input command is received by the DSM or a memory position recall using the memory set switch is received during the easy exit operation.

The easy entry/exit feature can be enabled/disabled on the message center. For information on programming vehicle settings in the message center, refer to the Owner's Literature.

Power Seat Operation - Passenger and Driver (Without Memory)

The seat control switches contain normally closed contacts which are grounded. An individual circuit is switched to voltage when a specific adjustment position is selected. The seat control switches are hard-wired directly to the applicable seat motors. The motor direction is determined by the polarity of voltage supplied from the seat control switch.

Multi-Contour Seat Operation

The multi-contour seats are independently controlled by the seat control switches (located on the outer side of the front seat cushions) or the FDIM (touchscreen). The driver and passenger front seats each contain a total of 7 inflatable bladders: 4 cushion bladders and 3 backrest lumbar bladders. The pressures for the lumbar bladders are displayed on the FDIM as a percentage of the maximum pressure.

There are 2 modes of operation: adjust or massage. Adjust mode allows pressure changes in one of the 3 lumbar bladders to be inflated or deflated to a desirable feel. Massage mode provides a sequence of inflation and deflation of the lumbar and cushion bladders to simulate a massage motion.

NOTE: Refer to the Owner's Literature for information how to select the various modes using the seat control switch or touchscreen buttons.

In Adjust mode:

- Each tap of the up or down buttons cycles through the following bladders: Upper lumbar, middle lumbar and lower lumbar.

- When the inflate/deflate buttons are pressed (or held), the pressure increases or decreases for the currently selected bladder.

- Pressing the mode select button toggles the seat to massage mode. The ignition must be on for massage mode to function.

In Massage mode:

- Each tap of the up or down buttons cycles between the different massage profiles.

- Each tap of the inflate/deflate buttons cycles between the intensity levels of massage (low, medium and high).

- Pressing the mode select button toggles the seat to adjust mode. Middle lumbar bladder will be selected automatically.

Each multi-contour seat can be restored to the original factory settings by pressing and holding the select button longer than 30 seconds. This resets all the adjust and massage settings (including any multi-contour driver seat settings associated to memory personality 1, 2 or 3).

Heated Seat Operation

The driver and passenger heated seat control buttons and indicators are located on the HVAC module. The heated seat system functions independently of the vehicle's climate control system. Each time the heated seat button is pressed, the system decreases one setting (the sequence is high, med, low, off, high, etc.).

When activated, the HVAC module supplies voltage to the selected seat heater circuit. Each seat cushion heater mat and backrest heater mat is connected in a series circuit to the HVAC module and powered by the output circuit for that seat. The HVAC module monitors inputs from a temperature sensor located in each seat cushion heater mat, and maintains seat temperature by cycling the heater circuits on/off. The heated seat remains on until the heated seat switch button is pressed to cycle the HVAC module off or the ignition is OFF.

If a fault is detected by the HVAC module, the module stops supplying voltage to that individual left or right seat the fault was detected on until the ignition is cycled off and then on.

Heated/Ventilated Seat Operation

The driver and passenger heated/ventilated seat buttons are selected from the HVAC module. The heated/ventilated seat system functions independently from the vehicle's climate control system.

Heat Operation

- The system control settings are indicated next to each heated/ventilated seat switch button. The first setting is high (3 indicators), the second setting is med (2 indicators) and the third is low (1 indicator) then off (no indicators).

- When activated, the SCME supplies voltage to the selected seat heater circuit. Each seat cushion heater mat and backrest heater mat is connected in a series circuit to the SCME and powered by the output circuit for that seat. The SCME monitors inputs from a temperature sensor located in each seat cushion heater mat, and maintains seat temperature by cycling the heater circuits on/off. The heated seat remains on until the heated seat switch button is pressed to cycle the SCME off or the ignition is off.

Ventilation Operation

- The seat cushion and backrest are each equipped with a blower motor assembly. Each blower motor draws air through the surface of the cushion and backrest through the foam. Once the system is activated, the SCME controls the blower speed depending on the heated/ventilated seat settings.

- The system control settings are based on the 3 indicators next to each heated/ventilated seat switch button. The first setting is high (3 indicators), the second setting is med (2 indicators) and the third is low (1 indicator) then off (no indicators).

Remote Start Climate Operation

Different climate control modes/preferences can be selected when the vehicle is started using the remote start feature. This can be accessed through the message center. For additional information on how to set the remote start preferences, refer to the Owner's Literature. When the driver seat and/or passenger seat is set to AUTO mode, the driver/passenger heated or heated/ventilated seat activates in full heat mode when the outside temperature is less than 0° C (32° F) and full cool mode (heated/ventilated seats only) when outside temperature is greater than 27° C (80° F) any time the vehicle is started using the remote start feature. No heated or heated/ventilated seat adjustments are recognized during remote start operation.

Component Description

Seat Control Switch - Without Memory

The seat control switch contains normally closed contacts which are grounded. When a specific adjustment position is selected, an individual circuit is switched to voltage.

Seat Control Switch - With Memory

The driver seat control switch is hard-wired to the DSM, which controls seat operation. When a specific seat adjustment position is selected, an individual circuit is switched to voltage.

Seat Control Switch - With Multi-Contour Seats

The driver seat control switch is hard-wired to the DSM, which controls seat operation. When a specific seat adjustment position is selected, an individual circuit is switched to voltage.

The driver and passenger seat control switches each contain a 5 position momentary contact switch which provides an analog signal (stepped resistance) to the SCMG or SCMH. The resistance range for each multi-contour button is as follows:

| Multi-Contour Switch | Resistance |

|---|---|

| Select | 26 to 54 ohms |

| Down | 113 to 125 ohms |

| Up | 196 to 221 ohms |

| Deflate | 317 to 351 ohms |

| Inflate | 483 to 533 ohms |

| No switch active | 573 to 634 ohms |

DSM

The driver seat control switch and power memory seat motors are hard-wired to the DSM. The DSM controls the operation of the power memory seat. The DSM communicates on the MS-CAN. The SCME is integral to the DSM. PMI is required on both the DSM and the SCME when a new DSM is installed. The DSM hard stop/soft stops must be set/reset any time a new DSM, driver front seat track or driver front seat backrest is installed.

Memory Set Switch

The memory set switch (part of the driver door lock switch assembly) contains 3 momentary contact switches. It is hard-wired to the DDM and is used to recall 1 of 3 memory positions stored in the DSM.

Driver Front Seat Track - Without Memory

There are 3 front seat track bi-directional motors present on power front seat tracks. All front seat track motors (horizontal, front height, rear height) are serviced with the front seat track. The front seat track motors move the power seat forward/backward and up/down depending on the polarity of voltage supplied from the seat control switch.

Driver Front Seat Track - With Memory

There are 3 front seat track bi-directional motors present on power front seat tracks. All front seat track motors (horizontal, front height, rear height) are serviced with the front seat track. The front seat track motors move the power seat forward/backward and up/down depending on the polarity of voltage supplied from the DSM.

Passenger Front Seat Track

The passenger power seat is equipped with 2 front seat track bi-directional motors. Both front seat track motors (horizontal and height) are serviced with the front seat track. The front seat track motors move the power seat forward/backward and up/down depending on the polarity of voltage supplied from the seat control switch.

Driver Front Seat Backrest

If equipped with power recline, the driver front seat backrest contains a bi-directional motor which is integral to the front seat backrest. The seat backrest motor moves the front seat backrest forward/backward depending on the polarity of voltage supplied from the DSM (if equipped with memory) or from the seat control switch.

Passenger Front Seat Backrest

If equipped with power recline, the passenger front seat backrest contains a bi-directional motor which is integral to the front seat backrest. The front seat backrest motor moves the front seat backrest forward/backward depending on the polarity of voltage supplied from the seat control switch.

FDIM

The FDIM (touchscreen) contains the multi-contour seat buttons.

HVAC Module

The HVAC module contains the heated seat or heated/ventilated seat control buttons. If equipped with heated seats, the HVAC module monitors the seat cushion temperature sensor and supplies heater current to the seat cushion and backrest heater mats until the desired setpoint temperature is reached. Once the setpoint temperature is reached, the HVAC module cycles the heater circuits on/off as required to maintain the setpoint temperature.

Heater Mat

If equipped with heated seats, the cushion heater mats are each equipped with a temperature sensor (thermistor) which provides feedback to the HVAC module. The cushion and backrest heater mats are connected in series.

Blower Motor

If equipped with heated/ventilated seats, the seat cushion and backrest are each equipped with a blower motor assembly. The blower motor assembly is controlled by the SCME.

SCME

If equipped with heated/ventilated seats, the SCME controls the operation of the heated/ventilated seat system. The SCME is integral to the DSM. PMI is required on both the DSM and the SCME when a new DSM is installed.

SCMG

The SCMG controls the operation of the driver multi-contour seat. PMI is required when a new SCMG is installed. The SCMG communicates on the MS-CAN. The SCMG controls the air pump (part of the front seat power lumbar assembly) which supplies the air pressure necessary to be diverted to the applicable air bladders as required for the desired mode(s) of operation.

SCMH

The SCMH controls the operation of the passenger multi-contour seat. PMI is required when a new SCMH is installed. The SCMH communicates on the MS-CAN. The SCMH controls the air pump (part of the front seat power lumbar assembly) which supplies the air pressure necessary to be diverted to the applicable air bladders as required for the desired mode(s) of operation.

Front Seat Power Lumbar Assembly

The front seat power lumbar assembly is mounted to the backrest (serviced as an assembly).

Front Seat Power Lumbar Assembly - Multi-Contour Seats

The front seat power lumbar assembly includes an air pump, air hoses and bladders (serviced as an assembly).

Front Seat Cushion Adjuster - Multi-Contour Seats

The front seat cushion adjuster includes air hoses and bladders (serviced as an assembly).

Description and Operation - Front Seats - Overview

Description and Operation - Front Seats - Overview

Overview

Driver Power Seat - Without Memory

The 6-way driver power seat is equipped with the following motors:

Front height motor (serviced with front seat track)

Rear height motor (serv..

Diagnosis and Testing - Front Seats

Diagnosis and Testing - Front Seats

Diagnostic Trouble Code (DTC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Informati..

Other information:

Ford Explorer 2020-2025 Owners Manual: CD (If equipped)

Once you select this option, the system returns you to the main audio screen. The current audio information appears on the screen. The following buttons are also available: You can use the forward, reverse, pause or play buttons to control the audio playback...

Ford Explorer 2020-2025 Owners Manual: Bulb Specification Chart

Replacement bulbs are specified in the chart below. Headlamp bulbs must be marked with an authorized D.O.T. marking for North America to make sure they have the proper lamp performance, light brightness, light pattern and safe visibility. The correct bulbs will not damage the lamp assembly or void the lamp assembly warranty and will provide quality bulb illumination time...

Categories

- Manuals Home

- 6th Generation Explorer Owners Manual

- 6th Generation Explorer Service Manual

- Diagnosis and Testing - Parking Brake - Vehicles With: Electric Brake Booster

- General Procedures - Brake Service Mode Activation and Deactivation

- Using Tether Straps

- New on site

- Most important about car

Gauges

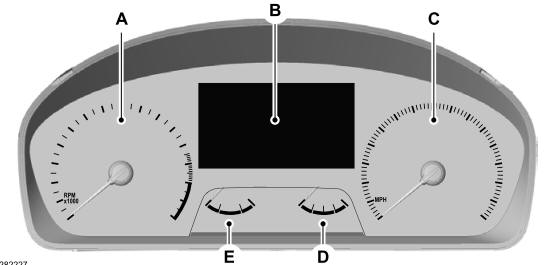

4 Inch Display

A - Tachometer.

B - Information display.

C - Speedometer.

D - Fuel gauge.

E - Engine coolant temperature gauge.

.jpg)

.jpg)

.jpg)