Ford Explorer: Automatic Transmission - 10-Speed Automatic Transmission – 10R60 / Diagnosis and Testing - Diagnostic Strategy

Overview

The diagnostic process for each transmission concern will vary depending on the symptoms and condition of the vehicle. The diagnostic process below is an efficient method to collect as much data as possible about the concern before performing a repair or removing the transmission from the vehicle for teardown and further inspection. Intermittent concerns and concerns that result in default or fail-safe operations can be difficult to diagnose.

https://magicaliptv.com/iptv-free-trials/Automatic Transmission Diagnosis

Many transmission faults will set one or more diagnostic trouble codes (DTCs) in the PCM/ TCM. In some instances a group of diagnostic trouble codes (DTCs) may indicate a particular fault. The transmission may only operate in default or failsafe modes while certain diagnostic trouble codes (DTCs) are set.

Begin diagnosis by carrying out the PCM self-tests:

-

KOEO and CMDTC

-

KOER and CMDTC

For vehicles equipped with a TCM, carry out the TCM self-test.

Record all diagnostic trouble codes (DTCs) and related freeze frame data. Clear the diagnostic trouble codes (DTCs) after recording the information.

Preliminary Inspection

The preliminary inspection will:

-

Find obvious causes for a concern by performing under hood and under vehicle visual inspections.

-

Adjust the selector lever linkage. (if equipped)

-

Collect a fluid sample.

PID Monitor/record on Road Test

Using the diagnostic trouble codes (DTCs) and freeze frame data as a guide, prepare the scan tool to make a recording of the event. Select the transmission parameter identifications (PIDs) that are related to the concern as well as parameter identifications (PIDs) for general automatic transmission operation. Since you may only get one or two chances to duplicate the concern, it is better to have more data on the recording. If possible, set datalogger to automatically start recording when a PID reaches a certain value. For example, you might want the recording to start 6 seconds before a fault PID changes from No Fault to Fault.

The PCM/ TCM may set a DTC after the first occurrence of the fault. Some diagnostic trouble codes (DTCs) may require up to 5 consecutive occurrences before setting. Drive the vehicle in a manner similar to the freeze frame data conditions if possible. If no freeze frame data is available, then perform this road test:

- Drive the vehicle normally for 1-3 minutes to warm up the fluid.

- From a stop, accelerate the vehicle to 100 kph (62 mph) with the shifts occurring at approximately 2000 rpm. Stay in 10th gear for 30 seconds or until the TCC applies. Repeat this two times.

- From a stop, accelerate the vehicle to 100 kph (62 mph) with the shifts occurring at approximately 3000 rpm. Stay in 10th gear for 30 seconds or until the TCC applies. Repeat this two times.

After

the road test, review the recording and check for newly set diagnostic

trouble codes (DTCs). Electrical fault diagnostic trouble codes (DTCs)

are diagnosed in pinpoint tests. Hydraulic, mechanical, and performance

fault diagnostic trouble codes (DTCs) are diagnosed in component tests.

Use the DTC chart for detailed diagnosis:

REFER to: DTC Chart and Pinpoint Tests - 2.3L EcoBoost (201kW/273PS) (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Diagnosis and Testing).

REFER to: DTC Chart and Pinpoint Tests - 3.0L EcoBoost (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Diagnosis and Testing).

REFER to: DTC Chart and Pinpoint Tests - 3.3L Duratec-V6 (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Diagnosis and Testing).

REFER to: DTC Chart and Pinpoint Tests - 3.0L EcoBoost (307-01B Automatic Transmission - 10-Speed Automatic Transmission – 10R80, Diagnosis and Testing).

REFER to: DTC Chart and Pinpoint Tests - 3.3L Duratec-V6 (307-01B Automatic Transmission - 10-Speed Automatic Transmission – 10R80, Diagnosis and Testing).

REFER to: DTC Chart and Pinpoint Tests - 3.3L Duratec-V6 – Hybrid (BP) (307-01C Automatic Transmission - 10-Speed Automatic Transmission – 10R80 MHT, Diagnosis and Testing).

If no diagnostic trouble codes (DTCs) are set, use the data collected and the Symptom Chart for further diagnosis.

Pinpoint Tests

The pinpoint tests are divided by component or system. Electrical pinpoint tests consist of a series of circuit checks to verify the integrity of the wiring harness between the PCM/ TCM and the solenoid or sensor. Mechanical pinpoint tests consist of a series of component tests and inspections to determine the root cause of the concern.

Component Tests

The component tests are divided by system. Each test lists the possible symptoms the system can exhibit. For each symptom is a list of components that could cause the symptom. The components are listed in least intrusive to most intrusive order.

Perform Repair

An automatic transmission contains over 400 individual components. All of these components must be in good working order. Many repairs are fairly straightforward. In these repairs you will:

- Clean and inspect all removed parts

- Attempt to determine the root cause of the failure

- Identify and repair/replace any related damaged parts

- Carefully document findings on the repair order

In the case of clutch failure where the transmission fluid is heavily contaminated with friction material, the transmission needs to be overhauled. The repair requires complete disassembly and cleaning of the transmission. All seals and gaskets (except the reusable pan gaskets) should be replaced.

Complete Repair

After reassembling the transmission, the following steps must be performed before returning the vehicle to the customer.

- Initial transmission fluid fill - this may be completed before the transmission is installed in the vehicle.

- Clear adaptive tables – required for overhaul and when the solenoid body has been replaced.

- Reset misfire monitor – required whenever the transmission has been removed.

- Road test until the transmission fluid is up to operating temperature. This is required to make sure transmission fluid cooler is full of transmission fluid.

- Perform adaptive drive cycle – required if the adaptive tables were cleared.

- Set transmission fluid level – transmission fluid is now at the correct temperature and the transmission fluid cooler has been purged of air.

- Verify the repair resolved the concern – this is also known as the post repair road test.

Description and Operation - Torque Converter

Description and Operation - Torque Converter

Overview

Item

Description

1

TCC solenoid

2

TCC regulator valve assembly

3

TCC apply circuit

4

..

Diagnosis and Testing - Preliminary Inspection

Diagnosis and Testing - Preliminary Inspection

Overview

The

preliminary inspection is part of Automatic Transmission Diagnosis.

The preliminary inspection is used to find obvious causes of

transmission concerns...

Other information:

Ford Explorer 2020-2025 Service Manual: Diagnosis and Testing - Driveshaft

Preliminary Inspection Visually inspect the CV joints for obvious signs of mechanical damage. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to the next step If the cause is not visually evident, verify the symptom and REFER to Symptom Chart: NVH...

Ford Explorer 2020-2025 Service Manual: Removal and Installation - Wheel Bearing and Wheel Hub

Special Tool(s) / General Equipment 205-D070 (D93P-1175-B) Remover, Front Wheel Hub Removal NOTICE: Suspension fasteners are critical parts that affect the performance of vital components and systems. Failure of these fasteners may result in major service expense...

Categories

- Manuals Home

- 6th Generation Explorer Owners Manual

- 6th Generation Explorer Service Manual

- Diagnosis and Testing - Parking Brake - Vehicles With: Electric Brake Booster

- Body and Paint

- Interior Trim and Ornamentation

- New on site

- Most important about car

Gauges

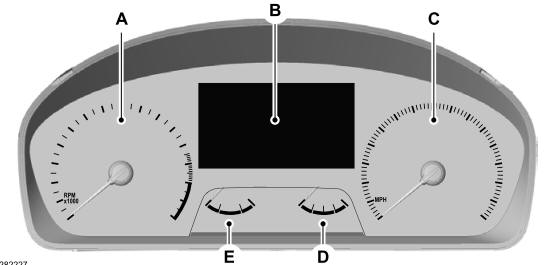

4 Inch Display

A - Tachometer.

B - Information display.

C - Speedometer.

D - Fuel gauge.

E - Engine coolant temperature gauge.