Ford Explorer: Engine - 2.3L EcoBoost (201kW/273PS) / Disassembly - Engine

Special Tool(s) /

General Equipment

.jpg) |

205-153

(T80T-4000-W)

Handle |

.jpg) |

303-050

(T70P-6000)

Lifting Bracket, Engine |

.jpg) |

303-1685

Alignment Tool, Camshaft |

.jpg) |

303-1687

Installer, VCT Solenoid Seal |

|

303-1689

Holding Tool, Crank Damper |

.jpg) |

303-409

(T92C-6700-CH)

Remover, Crankshaft Seal

TKIT-1992-FH/FMH/FLMH

TKIT-1993-LMH/MH |

.jpg) |

303-507

Timing Peg, Crankshaft TDC

TKIT-2001N-FLM

TKIT-2001N-ROW |

.jpg) |

307-005

(T59L-100-B)

Slide Hammer |

.jpg) |

310-206

Remover, Fuel Injector

TKIT-2009A-FLM |

| Mounting Stand |

| Plastic Scraper |

| Hose Clamp Remover/Installer |

Materials

| Name |

Specification |

Motorcraft® Silicone Gasket Remover

ZC-30-A |

-

|

Motorcraft® Metal Surface Prep Wipes

ZC-31-B |

-

|

Motorcraft® Metal Brake Parts Cleaner

PM-4-A, PM-4-B |

-

|

LHD AWD/LHD RWD

NOTICE:

Do not loosen or remove the crankshaft pulley bolt without

first installing the special tools as instructed in this procedure. The

crankshaft pulley and the crankshaft timing sprocket are not keyed to

the crankshaft. The crankshaft, the crankshaft sprocket and the pulley

are fitted together by friction. For that reason, the crankshaft

sprocket is also unfastened if the pulley bolt is loosened. Before any

repair requiring loosening or removal of the crankshaft pulley bolt, the

crankshaft and camshafts must be locked in place by the special service

tools, otherwise severe engine damage can occur.

NOTICE:

During engine repair procedures, cleanliness is extremely

important. All parts must be thoroughly cleaned and any foreign

material, including any material created while cleaning gasket surfaces,

that enters the oil passages, coolant passages or the oil pan, can

cause engine failure.

NOTICE:

The turbocharger compressor vanes can be damaged by even the

smallest particles. When removing any turbocharger or engine air intake

system component, ensure that no debris enters the system. Failure to

do so may result in damage to the turbocharger.

-

-

Remove the bolts and the flexplate.

-

Install engine on the mounting stand.

Use the General Equipment: Mounting Stand

-

Remove the engine lift equipment.

-

Remove Special Service Tool: 303-050

(T70P-6000)

Lifting Bracket, Engine.

-

If equipped, disconnect the block heater electrical connector and detach the wiring harness retainers.

-

Detach and remove the transmission vent tube.

-

Cut and discard the A/C belt.

-

Loosen the coolant pump pulley bolts.

-

-

Install the tool and release the tension on the accessory drive belt tensioner.

-

Remove the accessory drive belt.

-

Release the tension and remove the tool.

-

-

Disconnect the wiring harness electrical connectors.

-

Detach the wiring harness retainers.

-

-

Remove the bolts and the LH engine mount.

-

-

Disconnect the wiring harness electrical connectors.

-

Detach the wiring harness retainers.

-

-

Disconnect the wiring harness electrical connectors.

-

Detach the wiring harness retainers.

-

-

Disconnect the wiring harness electrical connectors.

-

Detach the wiring harness retainers.

-

-

Disconnect the wiring harness electrical connectors.

-

Detach the wiring harness retainers.

-

-

Disconnect the wiring harness electrical connectors.

-

Detach the wiring harness retainers.

-

Detach the wiring harness retainers and remove the engine wiring harness.

-

-

Detach the coolant hose retainer and remove the nut.

-

Remove the bolts and the thermostat housing.

-

-

Detach the coolant hose retainer.

-

Release the clamps and remove the coolant hose.

Use the General Equipment: Hose Clamp Remover/Installer

-

Remove the bolt and position the turbocharger coolant tube aside.

-

Remove and discard the turbocharger coolant tube O-ring seal.

-

-

Remove the coolant tube support bracket bolt.

-

Remove the bolt and the coolant tube support bracket.

-

-

Remove the EGR valve bracket nut.

-

Remove the bolt and the EGR valve bracket.

-

Remove the bolts and the coolant tube.

-

Inspect the coolant tube O-ring seal and replace if damaged.

-

Remove the bolt, nuts and the EGR valve.

-

Remove and discard EGR valve O-ring seal.

-

Remove and discard the EGR valve gasket.

-

Remove bolt, stud bolt and the EGR cooler bracket.

-

Remove the bolts and the EGR cooler.

-

Remove and discard the EGR cooler gaskets.

-

Remove the bolts and the coolant tube.

-

Discard the coolant tube O-ring seal.

-

-

Loosen the clamps and remove the EGR transducer hoses.

Use the General Equipment: Hose Clamp Remover/Installer

-

Remove the stud bolt and the EGR transducer assembly.

-

Remove the nuts, bolts and the EGR inlet tube assembly.

-

Remove and discard the EGR inlet tube assembly gasket.

-

Remove the bolts and the air cleaner bracket.

-

Remove the bolts and the coolant pump pulley.

-

Remove the bolts and the accessory drive belt tensioner.

-

Remove the stud bolts and the generator.

-

Remove the stud bolts, bolt and the A/C.

-

Remove the bolts and the A/C bracket.

-

-

Remove the nut, bolts and the RH engine mount.

-

Discard the nut and bolts.

LHD RWD

-

Remove the RH engine mount bracket.

LHD AWD

-

Remove the bolts and the LH axle connector.

-

Remove and discard the axle connector seal.

-

Remove the bolts and the front axle assembly.

-

Remove and discard the front axle assembly seal.

LHD AWD/LHD RWD

-

-

Detach the fuel rail harness electrical connector from the intake manifold.

-

Detach and disconnect the KS electrical connectors.

-

-

Disconnect the crankcase vent oil separator tube quick release coupling from the intake manifold.

Refer to: Quick Release Coupling (310-00A Fuel System - General Information - 2.3L EcoBoost (201kW/273PS), General Procedures).

-

Remove the bolts and the intake manifold.

-

-

If equipped, remove the bolt and the oil cooler.

-

If equipped, discard the oil cooler.

-

Remove the bolts and the oil filter adapter assembly.

-

-

Remove and discard the engine mount stud.

-

Remove the transmission bolt.

-

Release the clamps and remove the coolant hose.

Use the General Equipment: Hose Clamp Remover/Installer

-

Disconnect the crankcase vent oil separator tube and remove.

Refer to: Quick Release Coupling (310-00A Fuel System - General Information - 2.3L EcoBoost (201kW/273PS), General Procedures).

-

NOTE:

Note the position of the KS before removing.

Remove the bolts and the KS.

-

Remove the bolts and the crankcase vent separator.

-

Remove the bolts and the coolant pump adapter assembly.

-

Remove and discard the coolant pump adapter assembly gasket.

-

NOTE:

To release the fuel pressure in the high pressure

fuel tube, wrap the fuel injection pump flare nut with a shop towel to

absorb any residual fuel pressure during the loosening of the fuel

injection pump flare nut.

-

Remove the high-pressure fuel tube bolts.

-

Loosen the flare nuts, remove and discard the high-pressure fuel tube.

-

-

Remove the bolts and discard.

-

Remove the high-pressure fuel pump.

-

Remove and discard the high-pressure fuel pump O-ring seal.

-

Remove the high-pressure fuel pump tappet.

-

Remove the bolt coolant hose bracket.

-

Remove the bolts and discard the turbocharger-to-cylinder block oil return pipe.

-

Remove the nuts, bolt and the heat shield.

-

Remove the bolts and the cylinder block-to-turbocharger oil supply pipe.

-

Remove and discard the oil supply filter and O-ring seals.

-

Remove the bolt and the coolant outlet tube.

-

Remove and discard coolant outlet tube O-ring seal.

-

Remove the nuts and the turbocharger.

-

Remove and discard coolant outlet tube seal and O-ring seal.

-

-

Remove and discard the gasket.

-

Inspect and replace the studs if damaged.

-

Remove the stud bolts, bolts and the coolant outlet.

-

NOTE:

Use compressed air to remove any foreign material

from the ignition coil-on-plugs and surrounding area before removing the

ignition coil-on-plugs.

NOTE:

When removing the ignition coil-on-plugs, a slight twisting motion will break the seal and ease removal.

-

Remove the stud bolts and the ignition coil-on-plugs.

-

Remove the oil level indicator.

-

Loosen the fasteners and remove the valve cover.

-

Discard the valve cover gaskets.

-

-

If damaged, using the special tools, remove and discard the VCT oil control solenoid seals.

Use Special Service Tool: 303-1687

Installer, VCT Solenoid Seal.

, 205-153

(T80T-4000-W)

Handle.

-

NOTE:

Do not use metal scrapers, wire brushes, power

abrasive discs or other abrasive means to clean the sealing surfaces.

These tools cause scratches and gouges which make leak paths.

Clean the valve cover.

-

NOTICE:

Do not use metal scrapers, wire brushes, power

abrasive discs or other abrasive means to clean the sealing surfaces.

These tools cause scratches and gouges which make leak paths.

Make sure that the mating faces are clean and free of foreign material.

-

-

Disconnect the fuel rail wiring harness electrical connectors.

-

Detach the fuel rail wiring harness retainers and remove harness.

-

Remove the fuel rail insulator.

-

NOTICE:

Pull out the fuel rails in the direction of the fuel

injector axis or damage may occur to the fuel injectors.

NOTE:

Use compressed air and remove any dirt or foreign

material from the cylinder head, block and general surrounding area of

the fuel rail and injectors.

NOTE:

When removing the fuel rails, the fuel injectors may

remain in the fuel rails but normally remain in the cylinder head and

require the use of a Fuel Injector Remover tool to extract.

Remove and discard the bolts, then remove the fuel rail.

-

Remove any of the fuel injectors that remained in the fuel rail.

-

Remove any of the fuel injectors that remained in the cylinder head.

Use Special Service Tool: 307-005

(T59L-100-B)

Slide Hammer.

, 310-206

Remover, Fuel Injector.

-

Remove and discard the fuel injector clip.

-

NOTICE:

Do not attempt to cut the lower Teflon® seal without

first pulling it away from the fuel injector or damage to the injector

may occur.

NOTE:

Be very careful when removing the lower Teflon® seals, not to scratch, nick or gouge the fuel injectors.

-

Pull the lower Teflon® seal away from the injector.

-

Carefully cut and discard the lower fuel injector Teflon® seals.

-

Remove and discard the fuel injector seal and O-ring seal.

-

-

Remove the CHT sensor and the heat shield.

-

Remove the bolts and the CKP sensor.

-

Turn the crankshaft clockwise until the No.1 piston is 45 degrees BTDC using the guide holes on the engine front cover and the crankshaft pulley.

-

Remove the engine plug bolt.

-

Install Special Service Tool: 303-507

Timing Peg, Crankshaft TDC.

-

NOTE:

The special tool will contact the crankshaft and prevent it from turning past TDC. However, the crankshaft can still be rotated in the counterclockwise direction. The crankshaft must remain at the TDC position during the crankshaft pulley removal and installation.

NOTE:

The engine front cover is removed from graphic for clarity.

Rotate the crankshaft clockwise until it contacts the special tool.

Use Special Service Tool: 303-507

Timing Peg, Crankshaft TDC.

-

Remove the bolts and the high-pressure fuel pump drive unit.

-

NOTICE:

The Camshaft Alignment Tool is for camshaft

alignment only. Using this tool to prevent engine rotation can result in

engine damage.

NOTE:

The camshaft timing slots are offset. If the Camshaft Alignment Tool cannot be installed, remove the TDC Timing Peg and rotate the crankshaft three-fourths of a revolution clockwise and repeat the previous 2 steps of this procedure.

Install Special Service Tool: 303-1685

Alignment Tool, Camshaft.

-

NOTICE:

The crankshaft must remain in the TDC

position during removal of the pulley bolt or damage to the engine can

occur. Therefore, the crankshaft pulley must be held in place with the

special tool and the bolt should be removed using an air impact wrench

(1/2-in drive minimum).

-

Using the special tools, remove the bolt and the crankshaft pulley.

Use Special Service Tool: 303-1689

Holding Tool, Crank Damper.

-

Install the original crankshaft pulley bolt and washer.

-

NOTICE:

Use care not to damage the engine front cover or the crankshaft when removing the seal.

Using the crankshaft seal remover, remove the crankshaft front seal and discard.

Use Special Service Tool: 303-409

(T92C-6700-CH)

Remover, Crankshaft Seal.

-

Remove the original crankshaft pulley bolt and washer.

-

Remove the bolts and the engine front cover.

-

NOTICE:

Only use a 3M™ Roloc® Bristle Disk (2-in white, part

number 07528) in a suitable tool turning at the recommended speed of

15,000 rpm, to clean the engine front cover. Do not use metal scrapers,

wire brushes or any other power abrasive disk to clean. These tools

cause scratches and gouges that make leak paths.

-

Make sure that the mating faces of the engine front cover are clean and free of foreign material.

Refer to: RTV Sealing Surface Cleaning and Preparation (303-00 Engine System - General Information, General Procedures).

Material: Motorcraft® Silicone Gasket Remover

/ ZC-30-A

Material: Motorcraft® Metal Brake Parts Cleaner

/ PM-4-A, PM-4-B

Material: Motorcraft® Metal Surface Prep Wipes

/ ZC-31-B

-

Thoroughly wash the engine front cover to remove any

foreign material, including any abrasive particles created during the

cleaning process.

|

|

-

NOTICE:

Place clean, lint-free shop towels over exposed

engine cavities. Carefully remove the towels so foreign material is not

dropped into the engine. Any foreign material (including any material

created while cleaning gasket surfaces) that enters the oil passages or

the oil pan, may cause engine failure.

NOTICE:

Do not use metal scrapers, wire brushes, power

abrasive discs or 3M™ Roloc® Bristle Disk (2-in white part number 07528)

to clean the sealing surfaces. These tools cause scratches and gouges

that make leak paths. They also cause contamination that will cause

premature engine failure. Remove all traces of the gasket.

Make sure that the mating faces of the engine block and oil pan are clean and free of foreign material.

Refer to: RTV Sealing Surface Cleaning and Preparation (303-00 Engine System - General Information, General Procedures).

Use the General Equipment: Plastic Scraper

Material: Motorcraft® Silicone Gasket Remover

/ ZC-30-A

Material: Motorcraft® Metal Brake Parts Cleaner

/ PM-4-A, PM-4-B

Material: Motorcraft® Metal Surface Prep Wipes

/ ZC-31-B

.jpg) |

|

-

NOTICE:

Use an open-ended wrench on the flats of the camshaft to prevent the component from turning.

Loosen the exhaust VCT bolt.

-

NOTICE:

Use an open-ended wrench on the flats of the camshaft to prevent the component from turning.

Loosen the intake VCT bolt.

-

Remove the bolts and the timing chain tensioner.

-

Remove the bolts and the timing chain guide, timing chain and tensioner arm.

-

-

Remove the bolts and the VCT units.

-

Remove Special Service Tool: 303-1685

Alignment Tool, Camshaft.

-

Remove the bolts and the VCT oil control solenoids.

-

Remove bolts and front camshaft bearing cap.

-

NOTICE:

Failure to follow the camshaft loosening procedure can result in damage to the camshafts.

NOTE:

Note the location and orientation of each camshaft

bearing cap and the position of the camshaft lobes on the No. 1 cylinder

for installation reference.

-

Loosen the camshaft bearing caps in sequence 2 turns

at a time until all tension is released from the camshaft bearing caps

and remove the camshaft bearing caps and camshafts.

-

Inspect the camshaft bores for any scratches that can be felt by hand.

-

NOTE:

If the camshafts and valve tappets are to be reused,

mark the location of the valve tappets to make sure they are assembled

in their original positions.

Remove the valve tappets.

-

NOTE:

There are two numbers on the valve tappet, one is date code and the other is valve tappet thickness.

NOTE:

The date code “R0605” represents the year made (R), the month (06) and the day (05).

NOTE:

A tappet with the number N650 has the thickness of 3.650 mm.

Inspect the valve tappets.

-

If equipped, remove the block heater.

-

Remove the bolts, stud bolt and the cylinder head cover assembly.

-

Remove and discard the cylinder head cover gasket.

-

-

Remove the bolts and the cylinder head.

-

Remove and discard the cylinder head gasket.

-

Remove the cylinder block bushings.

-

NOTICE:

Do not use metal scrapers, wire brushes, power

abrasive discs or other abrasive means to clean the sealing surfaces.

These tools cause scratches and gouges that make leak paths. Use a

plastic scraping tool to remove all traces of the head gasket.

Clean the cylinder head sealing surfaces.

-

NOTICE:

Do not use metal scrapers, wire brushes, power

abrasive discs or other abrasive means to clean the sealing surfaces.

These tools cause scratches and gouges that make leak paths. Use a

plastic scraping tool to remove all traces of the head gasket.

NOTE:

Clean the cylinder head bolt holes in the cylinder

block. Make sure all coolant, oil or other foreign material is removed.

Clean the cylinder block sealing surfaces.

-

-

Check the cylinder block distortion.

Refer to: Cylinder Block Distortion (303-00 Engine System - General Information, General Procedures).

-

Check the cylinder head distortion.

Refer to: Cylinder Head Distortion (303-00 Engine System - General Information, General Procedures).

-

NOTICE:

Do not strike the oil pan sideways to remove, the

oil pan is doweled and will damage the oil pan and engine block.

NOTE:

AWD shown, RWD similar.

Remove the bolts and the oil pan.

-

Remove the bolts and the oil pickup and screen.

-

Discard the oil pickup and screen O-ring seal.

-

NOTICE:

Do not use wire brushes, power abrasive discs or 3M™

Roloc® Bristle Disk (2-in white, part number 07528) to clean the

sealing surfaces of the engine block. These tools cause scratches and

gouges that make leak paths. They also cause contamination that causes

premature engine failure. Remove all traces of the gasket.

Make sure that the mating faces of the engine block are clean and free of foreign material.

Refer to: RTV Sealing Surface Cleaning and Preparation (303-00 Engine System - General Information, General Procedures).

Use the General Equipment: Plastic Scraper

Material: Motorcraft® Silicone Gasket Remover

/ ZC-30-A

Material: Motorcraft® Metal Brake Parts Cleaner

/ PM-4-A, PM-4-B

Material: Motorcraft® Metal Surface Prep Wipes

/ ZC-31-B

.jpg) |

|

-

NOTICE:

Only use a 3M™ Roloc® Bristle Disk (2-in white, part

number 07528) in a suitable tool turning at the recommended speed of

15,000 rpm, to clean the oil pan. Do not use metal scrapers, wire

brushes or any other power abrasive disk to clean. These tools cause

scratches and gouges that make leak paths.

NOTE:

AWD shown, RWD similar.

-

Make sure that the mating faces of the oil pan are clean and free of foreign material.

Refer to: RTV Sealing Surface Cleaning and Preparation (303-00 Engine System - General Information, General Procedures).

Use the General Equipment: Plastic Scraper

Material: Motorcraft® Silicone Gasket Remover

/ ZC-30-A

Material: Motorcraft® Metal Brake Parts Cleaner

/ PM-4-A, PM-4-B

Material: Motorcraft® Metal Surface Prep Wipes

/ ZC-31-B

-

Thoroughly wash the oil pan to remove any foreign

material, including any abrasive particles created during the cleaning

process.

-

-

Remove the bolts and the crankshaft rear seal.

-

Discard the crankshaft rear seal.

-

Remove the crankshaft sprocket.

-

NOTE:

Make sure the Crankshaft TDC Timing Peg is still installed and the engine is still at TDC.

Rotate the crankshaft until it contacts the special tool.

-

NOTE:

Mark the balance shaft assembly front shafts on the top for reference that the balance shaft assembly is at TDC.

Index-mark the balance shaft assembly.

-

Remove the bolts and the oil outlet tube.

-

Inspect the oil outlet tube O-ring seals and replace if damaged.

-

-

Remove the oil inlet tube-to-bracket bolt.

-

Remove the bolt and the oil inlet tube bracket.

-

Remove the bolts and the oil inlet tube.

-

Inspect the oil inlet tube O-ring seals and replace if damaged.

-

NOTE:

Due to the precision interior construction of the balance shaft assembly, it should not be disassembled.

Remove the bolts and the balance shaft assembly.

-

Remove Special Service Tool: 303-507

Timing Peg, Crankshaft TDC.

-

-

Inspect ridge.

-

NOTE:

Remove the carbon buildup, do not scratch the cylinder wall. Remove all debris from the cylinder.

Clean with abrasive pad.

-

NOTE:

Clearly mark the connecting rods, connecting rod

caps and connecting rod bearings in numerical order for correct

orientation for reassembly.

Remove the bolts and the connecting rod caps.

-

NOTICE:

Do not scratch the cylinder walls or crankshaft journals with the connecting rod.

Remove the pistons.

-

NOTE:

Mark the position of the parts, so they can be installed in their original positions.

Remove the connecting rod bearings.

Refer to: Engine (303-01A Engine - 2.3L EcoBoost (201kW/273PS), Disassembly).

-

Remove the bolts and the main bearing beam.

-

NOTE:

If the main bearings are being reused, mark them in order for correct orientation and reassembly.

Remove the main bearing beam bearings.

-

Remove the crankshaft.

-

NOTE:

If the main bearings are being reused, mark them in order for correct orientation and reassembly.

NOTE:

The center bulkhead has the thrust bearing.

Remove the crankshaft main bearings.

-

Remove the bolts and the engine piston oil cooler valves.

-

If necessary, remove and discard the front cylinder block plug.

-

If necessary, remove and discard the rear cylinder block plug.

Special Tool(s) /

General Equipment

303-050

(T70P-6000)

Lifting Bracket, Engine

Adjustable Mounting Arm

Oil Drain Equipment

Side Cutter Pliers

Vehicle/Axle Stands

Cab..

Special Tool(s) /

General Equipment

303-1249Valve Spring CompressorTKIT-2006UF-FLMTKIT-2006UF-ROW

303-1567Sizer, Teflon SealTKIT-2010C-FLM

303-300

(T87C-6565-A)

Set, Valve Sprin..

Other information:

Removal

NOTICE:

The turbocharger compressor vanes can be damaged by even the

smallest particles. When removing any turbocharger or engine air intake

system component, ensure that no debris enters the system. Failure to

do so may result in damage to the turbocharger...

Overview

Driver Power Seat - Without Memory

The 6-way driver power seat is equipped with the following motors:

Front height motor (serviced with front seat track)

Rear height motor (serviced with front seat track)

Horizontal motor (serviced with front seat track)

The 8-way driver power seat is equipped with the following motors:

Front height motor (serviced with front ..

Categories

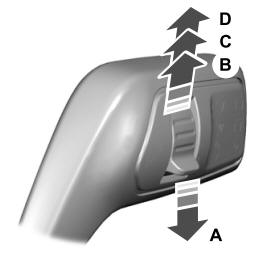

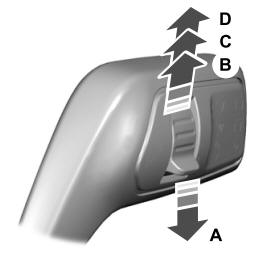

Push the lever up or down to operate

the windshield wipers.

Push the lever up or down to operate

the windshield wipers.

A - Single wipe.

read more

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Removal - Engine

Removal - Engine Disassembly and Assembly of Subassemblies - Cylinder Head

Disassembly and Assembly of Subassemblies - Cylinder Head Push the lever up or down to operate

the windshield wipers.

Push the lever up or down to operate

the windshield wipers.