Ford Explorer: Engine - 2.3L EcoBoost (201kW/273PS) / Removal and Installation - Camshafts

Special Tool(s) / General Equipment

.jpg) |

303-1685 Alignment Tool, Camshaft |

.jpg) |

303-507 Timing Peg, Crankshaft TDC TKIT-2001N-FLM TKIT-2001N-ROW |

| Feeler Gauge | |

Removal

NOTE: During engine repair procedures, cleanliness is extremely important. Any foreign material (including any material created while cleaning gasket surfaces) that enters the oil passages, coolant passages or the oil pan can cause engine failure.

NOTE: Do not rotate the camshafts unless instructed to in this procedure. Rotating the camshafts or crankshaft with timing components loosened or removed can cause serious damage to the valves and pistons.

-

With the vehicle in NEUTRAL, position it on a hoist.

Refer to: Jacking and Lifting - Overview (100-02 Jacking and Lifting, Description and Operation).

-

Release the fuel system pressure.

Refer to: Fuel System Pressure Release (310-00A Fuel System - General Information - 2.3L EcoBoost (201kW/273PS), General Procedures).

-

-

If the camshafts are being removed for servicing other components, remove the timing chain.

Refer to: Timing Chain (303-01A Engine - 2.3L EcoBoost (201kW/273PS), Removal and Installation).

-

If the camshafts are being replaced, remove the VCT units.

Refer to: Variable Camshaft Timing (VCT) Unit (303-01A Engine - 2.3L EcoBoost (201kW/273PS), Removal and Installation).

-

If the camshafts are being removed for servicing other components, remove the timing chain.

- Remove Special Service Tool: 303-1685 Alignment Tool, Camshaft.

.jpg) |

-

Remove the bolts and the VCT oil control solenoids.

.jpg) |

-

Remove the bolts and the front camshaft cap.

.jpg) |

-

NOTICE: Failure to follow the camshaft loosening procedure can result in damage to the camshafts.

NOTE: Note the location and orientation of each camshaft bearing cap and the position of the camshaft lobes on the No. 1 cylinder for installation reference.

-

Loosen the camshaft bearing caps in sequence 2 turns

at a time until all tension is released from the camshaft bearing caps

and remove the bolts, caps and camshafts.

-

Inspect the camshaft bores for any scratches that can be felt by hand.

-

Loosen the camshaft bearing caps in sequence 2 turns

at a time until all tension is released from the camshaft bearing caps

and remove the bolts, caps and camshafts.

.jpg) |

Installation

-

NOTICE: If any new parts are being installed (cylinder head, valves, tappets, camshafts) it is necessary to check the valve clearance, follow the next 17 steps exactly or serious damage to the engine may occur. If the original parts are being installed it is not necessary to check the valve clearance so proceed to step 18.

Install the crankshaft bolt, washer and place a paint mark on the crankshaft bolt at the 12 o'clock position.

.jpg) |

- Remove Special Service Tool: 303-507 Timing Peg, Crankshaft TDC.

.jpg) |

-

NOTE: Rotating the crankshaft will position all of the pistons below the deck of the cylinder block and allow the camshafts to be installed and the valve clearance checked without the possibility of damage to the valves or pistons.

Using the crankshaft bolt and washer, rotate the crankshaft clockwise 270 degrees until the paint mark is at the 9 o'clock position.

.jpg) |

-

NOTICE: Failure to follow the camshaft tightening procedure can result in damage to the camshafts.

-

Lubricate the camshafts, camshaft journals and camshaft bearing caps with clean engine oil and install.

-

Install the camshaft caps and the bolts.

-

Tighten 2 turns at a time in the sequence shown in 2 stages.

Torque:

Stage 1: 62 lb.in (7 Nm)

Stage 2: 142 lb.in (16 Nm)

-

Lubricate the camshafts, camshaft journals and camshaft bearing caps with clean engine oil and install.

.jpg) |

-

NOTICE: The camshaft seal gaps must be at the 12 o'clock position or damage to the engine may occur.

Inspect and position the camshaft seals gaps at the 12 o'clock position as shown.

.jpg) |

-

Lubricate the camshafts journals with clean engine oil.

.jpg) |

-

Install the camshaft cap and the bolts.

Torque:

Stage 1: 62 lb.in (7 Nm)

Stage 2: 142 lb.in (16 Nm)

.jpg) |

-

NOTICE: Do not remove the spark plugs when the engine is hot or cold soaked. Spark plug thread or cylinder head damage can occur. Make sure the engine is warm (hand touch after cooling down) prior to spark plug removal.

NOTICE: If a spark plug is dropped, internal damage may result and the spark plug must be discarded. The use of a damaged spark plug may cause cylinder misfire resulting in engine damage.

NOTE: Only use hand tool to remove the spark plugs.

Remove the spark plugs.

.jpg) |

-

-

Using the flats of the camshaft, rotate the camshaft

to place the cam lobe at base circle, with the lobe pointed away from

the tappet.

-

Use a feeler gauge to measure the clearance of each valve and record its location.

Use the General Equipment: Feeler Gauge

-

Repeat to measure all of the lobe/tappet clearances.

-

Using the flats of the camshaft, rotate the camshaft

to place the cam lobe at base circle, with the lobe pointed away from

the tappet.

.jpg) |

-

Valve tappet assembly grade chart

-

Grade

-

Id Mark

-

Thickness (mm)

-

Grade

.jpg) |

-

NOTE: There are two numbers on the valve tappet, one is date code and the other is valve tappet thickness.

NOTE: The date code “R0605” represents the year made (R), the month (06) and the day (05).

NOTE: A tappet with the number N650 has the thickness of 3.650 mm.

NOTE: Select tappets using this formula: tappet thickness = measured clearance + the existing tappet thickness - nominal clearance.

NOTE: The nominal clearance is:

- intake: 0.25 mm (0.0095 in).

- exhaust: 0.36 mm (0.0142 in).

NOTE: The acceptable clearances after being fully installed are:

- intake: 0.19-0.31 mm (0.0075-0.0122 in).

- exhaust: 0.3-0.42 mm (0.0118-0.0165 in).

-

NOTE: Only use hand tool to install the spark plugs.

Install the spark plugs.

Torque: 106 lb.in (12 Nm)

.jpg) |

-

Remove the bolts and the front camshaft cap.

.jpg) |

-

NOTICE: Failure to follow the camshaft loosening procedure can result in damage to the camshafts.

Loosen the camshaft bearing caps in sequence 2 turns at a time until all tension is released from the camshaft bearing caps and remove the bolts, caps and camshafts.

.jpg) |

-

- Install Special Service Tool: 303-507 Timing Peg, Crankshaft TDC.

.jpg) |

-

NOTE: Rotating the crankshaft will position the engine at TDC and allow you to install the camshafts in the same position as noted during the disassembly.

Rotate the crankshaft clockwise 90 degrees so the crankshaft contacts the crankshaft timing peg.

.jpg) |

-

If necessary, replace and lubricate any tappets with the

correct tappets selected during the valve clearance check.

.jpg) |

-

NOTICE: Install the camshafts with the alignment slots in the camshafts lined up so the Camshaft Alignment Plate can be installed without rotating the camshafts. Make sure the lobes on the No. 1 cylinder are in the same position as noted in the removal procedure. Rotating the camshafts when the timing chain is removed, or installing the camshafts 180 degrees out of position can cause severe damage to the valves and pistons.

NOTICE: Failure to follow the camshaft tightening procedure can result in damage to the camshafts.

-

Lubricate the camshaft, camshaft journals and camshaft bearing caps with clean engine oil.

-

Install the camshafts, caps, bolts and tighten the

camshaft bearing cap bolts one turn at a time, until finger-tight.

Torque:

Stage 1: 62 lb.in (7 Nm)

Stage 2: 142 lb.in (16 Nm)

-

Lubricate the camshaft, camshaft journals and camshaft bearing caps with clean engine oil.

.jpg) |

-

NOTICE: The camshaft seal gaps must be at the 12 o'clock position or damage to the engine may occur.

Inspect and position the camshaft seals gaps at the 12 o'clock position as shown.

.jpg) |

-

Lubricate the camshafts journals with clean engine oil.

.jpg) |

-

Install the camshaft cap and the bolts.

Torque:

Stage 1: 62 lb.in (7 Nm)

Stage 2: 142 lb.in (16 Nm)

.jpg) |

-

Install the VCT oil control solenoids and the bolts.

Torque: 97 lb.in (11 Nm)

.jpg) |

-

NOTICE: The Camshaft Alignment Tool is for camshaft alignment only. Using this tool to prevent engine rotation can result in engine damage.

Install the special tool into the slots on the back of the camshafts.

Install Special Service Tool: 303-1685 Alignment Tool, Camshaft.

.jpg) |

-

-

If the camshafts were removed for servicing other components, install the timing chain.

Refer to: Timing Chain (303-01A Engine - 2.3L EcoBoost (201kW/273PS), Removal and Installation).

-

If the camshafts were replaced, install the VCT units.

Refer to: Variable Camshaft Timing (VCT) Unit (303-01A Engine - 2.3L EcoBoost (201kW/273PS), Removal and Installation).

-

If the camshafts were removed for servicing other components, install the timing chain.

-

Pressurize the fuel system.

Refer to: Fuel System Pressure Release (310-00A Fuel System - General Information - 2.3L EcoBoost (201kW/273PS), General Procedures).

General Procedures - Valve Clearance Adjustment

General Procedures - Valve Clearance Adjustment

Special Tool(s) /

General Equipment

Feeler Gauge

Check

Remove the valve cover.

Refer to: Valve Cover (303-01A Engine - 2.3L EcoBoost (201kW/273PS), Removal and Installation)...

Removal and Installation - Crankshaft Front Seal

Removal and Installation - Crankshaft Front Seal

Special Tool(s) /

General Equipment

303-096

(T74P-6150-A)

Installer, Camshaft Front Oil SealTKIT-2009TC-F

303-409

(T92C-6700-CH)

Remover, Crankshaft SealTKIT-1992-FH/FMH/FLMHTKIT-199..

Other information:

Ford Explorer 2020-2025 Owners Manual: Emergency Call Requirements

WARNING: Do not wait for 911 Assist to make an emergency call if you can do it yourself. Dial emergency services immediately to avoid delayed response time which could increase the risk of serious injury or death after a crash. If you do not hear 911 Assist within five seconds of the crash, the system or phone may be damaged or non-functional...

Ford Explorer 2020-2025 Service Manual: Description and Operation - Electronic Engine Controls - Component Location

E..

Categories

- Manuals Home

- 6th Generation Explorer Owners Manual

- 6th Generation Explorer Service Manual

- Engine - 2.3L EcoBoost (201kW/273PS)

- Body and Paint

- Body and Paint

- New on site

- Most important about car

Gauges

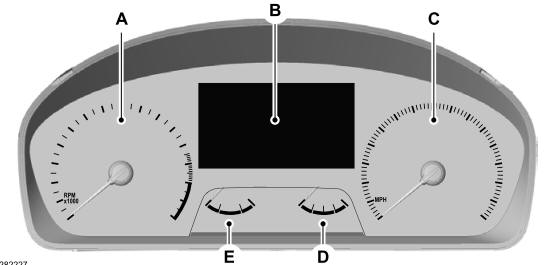

4 Inch Display

A - Tachometer.

B - Information display.

C - Speedometer.

D - Fuel gauge.

E - Engine coolant temperature gauge.